Page 190 - Boiler plant and distribution system optimization manual

P. 190

Over 100 Ways to Improve Efficiency 175

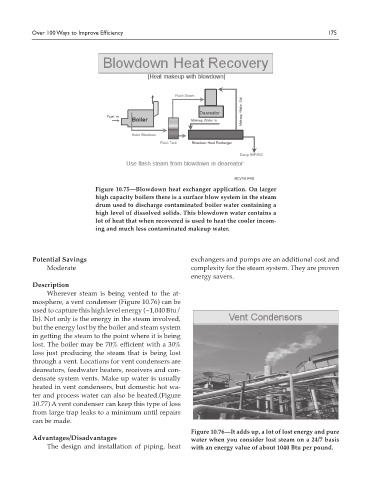

Figure 10.75—Blowdown heat exchanger application. On larger

high capacity boilers there is a surface blow system in the steam

drum used to discharge contaminated boiler water containing a

high level of dissolved solids. This blowdown water contains a

lot of heat that when recovered is used to heat the cooler incom-

ing and much less contaminated makeup water.

Potential Savings exchangers and pumps are an additional cost and

Moderate complexity for the steam system. They are proven

energy savers.

Description

Wherever steam is being vented to the at-

mosphere, a vent condenser (Figure 10.76) can be

used to capture this high level energy (~1,040 Btu/

lb). Not only is the energy in the steam involved,

but the energy lost by the boiler and steam system

in getting the steam to the point where it is being

lost. The boiler may be 70% efficient with a 30%

loss just producing the steam that is being lost

through a vent. Locations for vent condensers are

deareators, feedwater heaters, receivers and con-

densate system vents. Make up water is usually

heated in vent condensers, but domestic hot wa-

ter and process water can also be heated.(Figure

10.77) A vent condenser can keep this type of loss

from large trap leaks to a minimum until repairs

can be made.

Figure 10.76—It adds up, a lot of lost energy and pure

Advantages/Disadvantages water when you consider lost steam on a 24/7 basis

The design and installation of piping, heat with an energy value of about 1040 Btu per pound.