Page 188 - Boiler plant and distribution system optimization manual

P. 188

Over 100 Ways to Improve Efficiency 173

Figure 10.71—Combustion air preheater and feedwater heater

unit installed in processing plant boiler exhaust system.

6. WASTE HEAT RECOVERY BOILERS an excellent source of free energy.

The “combined cycle” uses high temperature

Cost turbine exhaust to generate steam for a second

High generator utilizing a waste heat recovery boiler.

The steam from the turbine exhaust is also used

Savings making a very efficient operation.

High

Description

There are many processes and appli-

cations where heat is wasted that could

be captured in a waste heat recovery

boiler (Figure 10.72) especially where ex-

haust temperatures are 500°F and above.

This type of system has been with us for

a long time, but opportunities still exist to

tap this virtually free source of steam and

heat. The classic use of waste heat boil-

ers is on reciprocating engines (Figure

10.73 and Figure 10.74) and gas turbines

which have exhaust temperatures near

the 1,000°F range.

Advantages/Disadvantages

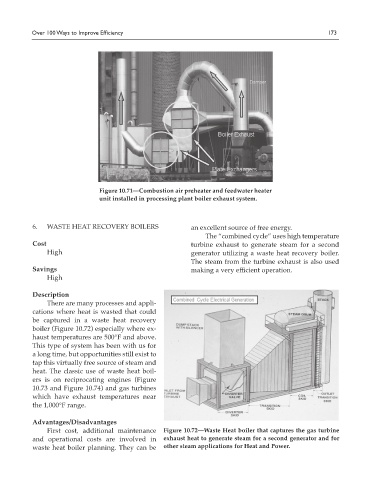

First cost, additional maintenance Figure 10.72—Waste Heat boiler that captures the gas turbine

and operational costs are involved in exhaust heat to generate steam for a second generator and for

waste heat boiler planning. They can be other steam applications for Heat and Power.