Page 184 - Boiler plant and distribution system optimization manual

P. 184

Over 100 Ways to Improve Efficiency 169

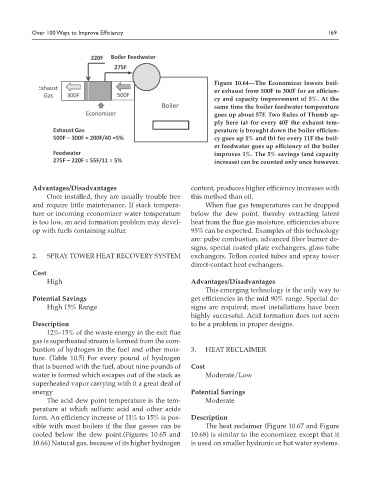

Figure 10.64—The Economizer lowers boil-

er exhaust from 500F to 300F for an efficien-

cy and capacity improvement of 5%. At the

same time the boiler feedwater temperature

goes up about 57F. Two Rules of Thumb ap-

ply here (a) for every 40F the exhaust tem-

perature is brought down the boiler efficien-

cy goes up 1% and (b) for every 11F the boil-

er feedwater goes up efficiency of the boiler

improves 1%. The 5% savings (and capacity

increase) can be counted only once however.

Advantages/Disadvantages content, produces higher efficiency increases with

Once installed, they are usually trouble free this method than oil.

and require little maintenance. If stack tempera- When flue gas temperatures can be dropped

ture or incoming economizer water temperature below the dew point, thereby extracting latent

is too low, an acid formation problem may devel- heat from the flue gas moisture, efficiencies above

op with fuels containing sulfur. 95% can be expected. Examples of this technology

are: pulse combustion, advanced fiber burner de-

signs, special coated plate exchangers, glass tube

2. SPRAY TOWER HEAT RECOVERY SYSTEM exchangers, Teflon coated tubes and spray tower

direct-contact heat exchangers.

Cost

High Advantages/Disadvantages

This emerging technology is the only way to

Potential Savings get efficiencies in the mid 90% range. Special de-

High 15% Range signs are required; most installations have been

highly successful. Acid formation does not seem

Description to be a problem in proper designs.

12%-15% of the waste energy in the exit flue

gas is superheated stream is formed from the com-

bustion of hydrogen in the fuel and other mois- 3. HEAT RECLAIMER

ture. (Table 10.5) For every pound of hydrogen

that is burned with the fuel, about nine pounds of Cost

water is formed which escapes out of the stack as Moderate/Low

superheated vapor carrying with it a great deal of

energy Potential Savings

The acid dew point temperature is the tem- Moderate

perature at which sulfuric acid and other acids

form. An efficiency increase of 11% to 15% is pos- Description

sible with most boilers if the flue gasses can be The heat reclaimer (Figure 10.67 and Figure

cooled below the dew point.(Figures 10.65 and 10.68) is similar to the economizer, except that it

10.66) Natural gas, because of its higher hydrogen is used on smaller hydronic or hot water systems.