Page 185 - Boiler plant and distribution system optimization manual

P. 185

170 Boiler Plant and Distribution System Optimization Manual

Table 10.5—Sources of vaporized water in boiler exhaust. Combustion pro-

cesses create lots of moisture which turns to superheated steam leaving the

stack with a lot of energy; a major loss of efficiency.

——————————————————————————————————

Sources of vaporized

Water in Boiler Exhaust

Every pound of hydrogen burned forms 9 pounds of water

Natural gas is 22.5% hydrogen (2 lb/lb fuel)

Distillate oil is 12.5% hydrogen (1.25 lb/lb fuel)

Residual oil is 9.5% hydrogen (0.86 lb/lb fuel)

Bituminous coal is about 5%

hydrogen but may contain

5% to 25% fixed moisture by wt. (0.45 to 2.25 lb/lb fuel)

Other Sources:

1. Atomizing steam at burners

2. Soot blowers

3. Tube leaks

4. Surface moisture on coal [rain]

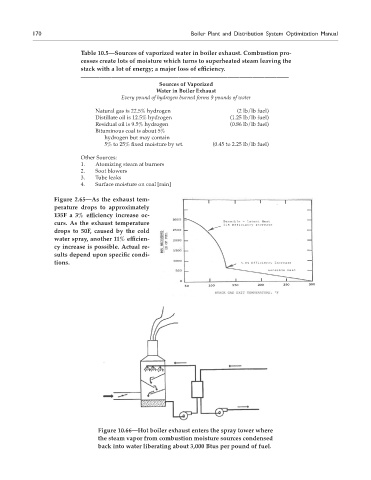

Figure 2.65—As the exhaust tem-

perature drops to approximately

135F a 3% efficiency increase oc-

curs. As the exhaust temperature

drops to 50F, caused by the cold

water spray, another 11% efficien-

cy increase is possible. Actual re-

sults depend upon specific condi-

tions.

Figure 10.66—Hot boiler exhaust enters the spray tower where

the steam vapor from combustion moisture sources condensed

back into water liberating about 3,000 Btus per pound of fuel.