Page 189 - Boiler plant and distribution system optimization manual

P. 189

174 Boiler Plant and Distribution System Optimization Manual

over 300°F depending on Boiler pressure and it

contains a lot of energy that can be wasted if it

is not put back to work in the boiler somehow.

About 15% of the blowdown water will flash to

low pressure steam so it is a very good source

of low pressure steam and is usually used in the

deareator/feedwater heater. This steam can be re-

covered in a flash tank and the rest of the heat

contained in the hot water in a heat exchanger. If

steam is not needed, than a simpler heat exchang-

er recovery configuration can be used to just heat

feedwater. (Figure 10.75)

Advantages/Disadvantages

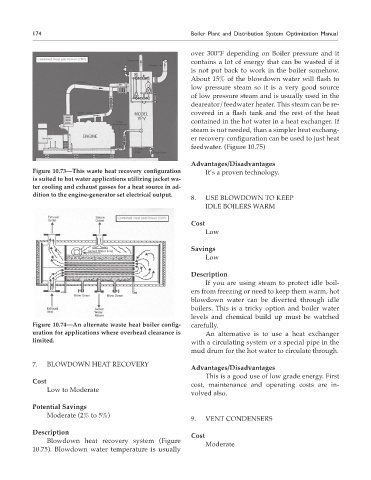

Figure 10.73—This waste heat recovery configuration It’s a proven technology.

is suited to hot water applications utilizing jacket wa-

ter cooling and exhaust gasses for a heat source in ad-

dition to the engine-generator set electrical output.

8. USE BLOWDOWN TO KEEP

IDLE BOILERS WARM

Cost

Low

Savings

Low

Description

If you are using steam to protect idle boil-

ers from freezing or need to keep them warm, hot

blowdown water can be diverted through idle

boilers. This is a tricky option and boiler water

levels and chemical build up must be watched

Figure 10.74—An alternate waste heat boiler config- carefully.

uration for applications where overhead clearance is An alternative is to use a heat exchanger

limited. with a circulating system or a special pipe in the

mud drum for the hot water to circulate through.

7. BLOWDOWN HEAT RECOVERY

Advantages/Disadvantages

This is a good use of low grade energy. First

Cost

cost, maintenance and operating costs are in-

Low to Moderate

volved also.

Potential Savings

Moderate (2% to 5%)

9. VENT CONDENSERS

Description

Cost

Blowdown heat recovery system (Figure

Moderate

10.75). Blowdown water temperature is usually