Page 250 - Boiler plant and distribution system optimization manual

P. 250

Waste Heat Recovery 235

pated. The cast iron sleeve will corrode, but it can the metal, or stack wall, that is in contact with the

be replaced at normal maintenance intervals. The flue gas that will determine the extent of acid cor-

cast iron sleeves protect the carbon steel tubes rosion. Stack insulation will aid in keeping stack

from contact with corrosive gases. temperatures above the ADP.

Alternatives to insulation are high tempera-

Improve Fluid Flow Arrangement ture corrosion-resistant stack material such as

Using parallel-flow tube arrangements rath- Cor-Ten or Fiberglass reinforced plastic.

er than counter-flow arrangements increases

economizer skin temperature. With the parallel

flow arrangement, cold feedwater enters where CONDENSING THE MOISTURE IN

the stack gas is the hottest, thus raising the tube FLUE GASSES

surface temperature slightly.

The major limitation to increased boiler effi-

Modulate Feedwater ciencies Is the amount of energy tied up in latent

Flow through the Economizer heat. Until recent years equipment has not been

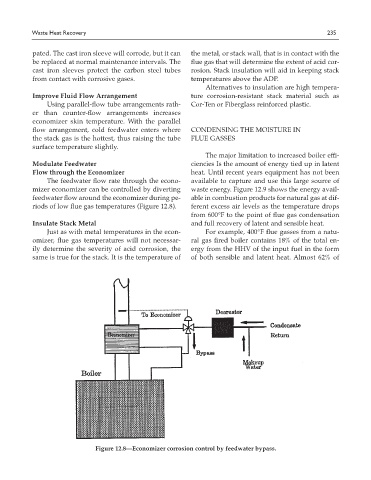

The feedwater flow rate through the econo- available to capture and use this large source of

mizer economizer can be controlled by diverting waste energy. Figure 12.9 shows the energy avail-

feedwater flow around the economizer during pe- able in combustion products for natural gas at dif-

riods of low flue gas temperatures (Figure 12.8). ferent excess air levels as the temperature drops

from 600°F to the point of flue gas condensation

Insulate Stack Metal and full recovery of latent and sensible heat.

Just as with metal temperatures in the econ- For example, 400°F flue gasses from a natu-

omizer, flue gas temperatures will not necessar- ral gas fired boiler contains 18% of the total en-

ily determine the severity of acid corrosion, the ergy from the HHV of the input fuel in the form

same is true for the stack. It is the temperature of of both sensible and latent heat. Almost 62% of

Figure 12.8—Economizer corrosion control by feedwater bypass.