Page 270 - Boiler plant and distribution system optimization manual

P. 270

Chapter 14

Steam Traps

When steam expends its energy, by giving up

its heat or by doing work, it condenses back into

water (Figure 14.1). This water must be removed

from the pathway of the steam so it will not inter-

fere with the function of the steam system. Once

removed, the condensate, pure hot water, should

be returned to the boiler where it is again heated

to produce more steam.

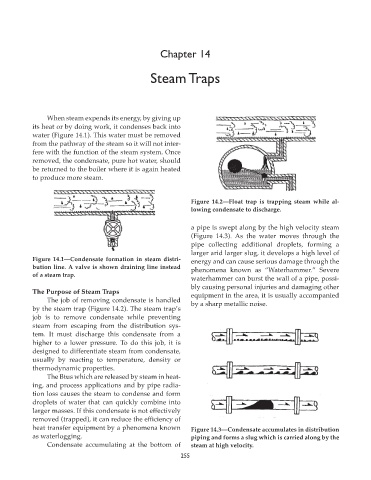

Figure 14.2—Float trap is trapping steam while al-

lowing condensate to discharge.

a pipe is swept along by the high velocity steam

(Figure 14.3). As the water moves through the

pipe collecting additional droplets, forming a

larger arid larger slug, it develops a high level of

Figure 14.1—Condensate formation in steam distri-

energy and can cause serious damage through the

bution line. A valve is shown draining line instead

phenomena known as “Waterhammer.” Severe

of a steam trap.

waterhammer can burst the wall of a pipe, possi-

bly causing personal injuries and damaging other

The Purpose of Steam Traps

equipment in the area, it is usually accompanied

The job of removing condensate is handled

by a sharp metallic noise.

by the steam trap (Figure 14.2). The steam trap’s

job is to remove condensate while preventing

steam from escaping from the distribution sys-

tem. It must discharge this condensate from a

higher to a lower pressure. To do this job, it is

designed to differentiate steam from condensate,

usually by reacting to temperature, density or

thermodynamic properties.

The Btus which are released by steam in heat-

ing, and process applications and by pipe radia-

tion loss causes the steam to condense and form

droplets of water that can quickly combine into

larger masses. If this condensate is not effectively

removed (trapped), it can reduce the efficiency of

heat transfer equipment by a phenomena known Figure 14.3—Condensate accumulates in distribution

as waterlogging. piping and forms a slug which is carried along by the

Condensate accumulating at the bottom of steam at high velocity.

255