Page 273 - Boiler plant and distribution system optimization manual

P. 273

258 Boiler Plant and Distribution System Optimization Manual

used to protect pressure reducing valves and moving parts are subject to wear, corrosion and

traps and are generally installed to keep the sys- eventual failure.

tem clean. The strainer body is a low point in the Most traps function intermittently. During

system which accumulates condensate natural- the closed portion of their cycle, the leg of water

ly, reducing the effective area of strainer screen. that accumulates encourages the formation of a

In the case of a valve down stream that has been mildly corrosive acid and the cycling itself caus-

closed, some condensate will be picked up by the es temperature fluctuations which accelerate the

flow when it is opened, impacting the valve seat problem.

with dirty condensate. A typical trap may open and close several

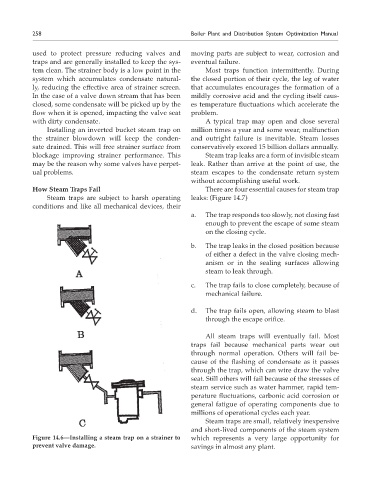

Installing an inverted bucket steam trap on million times a year and some wear, malfunction

the strainer blowdown will keep the conden- and outright failure is inevitable. Steam losses

sate drained. This will free strainer surface from conservatively exceed 15 billion dollars annually.

blockage improving strainer performance. This Steam trap leaks are a form of invisible steam

may be the reason why some valves have perpet- leak. Rather than arrive at the point of use, the

ual problems. steam escapes to the condensate return system

without accomplishing useful work.

How Steam Traps Fail There are four essential causes for steam trap

Steam traps are subject to harsh operating leaks: (Figure 14.7)

conditions and like all mechanical devices, their

a. The trap responds too slowly, not closing fast

enough to prevent the escape of some steam

on the closing cycle.

b. The trap leaks in the closed position because

of either a defect in the valve closing mech-

anism or in the sealing surfaces allowing

steam to leak through.

c. The trap fails to close completely, because of

mechanical failure.

d. The trap fails open, allowing steam to blast

through the escape orifice.

All steam traps will eventually fail. Most

traps fail because mechanical parts wear out

through normal operation. Others will fail be-

cause of the flashing of condensate as it passes

through the trap, which can wire draw the valve

seat. Still others will fail because of the stresses of

steam service such as water hammer, rapid tem-

perature fluctuations, carbonic acid corrosion or

general fatigue of operating components due to

millions of operational cycles each year.

Steam traps are small, relatively inexpensive

and short-lived components of the steam system

Figure 14.6—Installing a steam trap on a strainer to which represents a very large opportunity for

prevent valve damage. savings in almost any plant.