Page 278 - Boiler plant and distribution system optimization manual

P. 278

Steam Traps 263

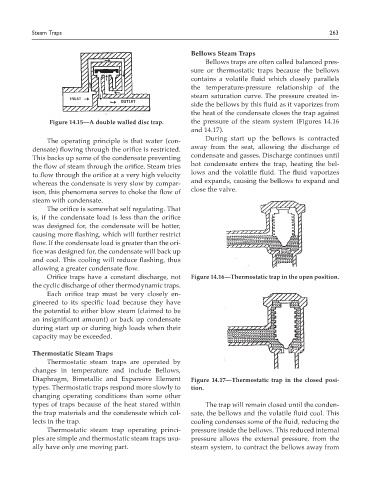

Bellows Steam Traps

Bellows traps are often called balanced pres-

sure or thermostatic traps because the bellows

contains a volatile fluid which closely parallels

the temperature-pressure relationship of the

steam saturation curve. The pressure created in-

side the bellows by this fluid as it vaporizes from

the heat of the condensate closes the trap against

Figure 14.15—A double walled disc trap. the pressure of the steam system (Figures 14.16

and 14.17).

The operating principle is that water (con- During start up the bellows is contracted

densate) flowing through the orifice is restricted. away from the seat, allowing the discharge of

This backs up some of the condensate preventing condensate and gasses. Discharge continues until

the flow of steam through the orifice. Steam tries hot condensate enters the trap, heating the bel-

to flow through the orifice at a very high velocity lows and the volatile fluid. The fluid vaporizes

whereas the condensate is very slow by compar- and expands, causing the bellows to expand and

ison, this phenomena serves to choke the flow of close the valve.

steam with condensate.

The orifice is somewhat self regulating. That

is, if the condensate load is less than the orifice

was designed for, the condensate will be hotter,

causing more flashing, which will further restrict

flow. If the condensate load is greater than the ori-

fice was designed for, the condensate will back up

and cool. This cooling will reduce flashing, thus

allowing a greater condensate flow.

Orifice traps have a constant discharge, not Figure 14.16—Thermostatic trap in the open position.

the cyclic discharge of other thermodynamic traps.

Each orifice trap must be very closely en-

gineered to its specific load because they have

the potential to either blow steam (claimed to be

an insignificant amount) or back up condensate

during start up or during high loads when their

capacity may be exceeded.

Thermostatic Steam Traps

Thermostatic steam traps are operated by

changes in temperature and include Bellows,

Diaphragm, Bimetallic and Expansive Element Figure 14.17—Thermostatic trap in the closed posi-

types. Thermostatic traps respond more slowly to tion.

changing operating conditions than some other

types of traps because of the heat stored within The trap will remain closed until the conden-

the trap materials and the condensate which col- sate, the bellows and the volatile fluid cool. This

lects in the trap. cooling condenses some of the fluid, reducing the

Thermostatic steam trap operating princi- pressure inside the bellows. This reduced internal

ples are simple and thermostatic steam traps usu- pressure allows the external pressure, from the

ally have only one moving part. steam system, to contract the bellows away from