Page 280 - Boiler plant and distribution system optimization manual

P. 280

Steam Traps 265

Table 14.1—Annual cost of steam loss from traps for mance better than that is difficult in the av-

100 psi steam at $5.00 per 1000 pounds. erage plant. Failed-trap percentages as high

as 50% in some plants showed up during the

early days of the energy crisis, and occasion-

ally we see such performance still.”

Power Magazine

April, 1980

“Experience indicates, that in plants without

planned steam trap maintenance, between

10% and 50% of the traps are malfunction-

ing at any given time—as a result of errors in

sizing, misapplication or inadequate mainte-

nance.”

facility may fail open at any time and the losses,

Plant Engineering

if it is not found and repaired quickly, can be very

March 5, 1981

large. Failure could occur at any time, even the

day after the last inspection. Figure 14.20 shows

“Most plants can save 10-20% of fuel cost

how flash steam and steam from failed steam

simply by having a formal, active steam trap

traps vents to the atmosphere.

program...For the first year, a return of $1

To determine how often traps will fail has

million in energy savings for each $300,000

so many variables, that any conclusion should

spent upgrading the system is the rule rather

be based on actual conditions at a specific facili-

than the exception.”

ty. Some generalizations have emerged over the

Chemical Engineering

years. There is very little information on this topic.

February 9, 1981

“Trap life should be 4-5 years average. For

a plant with 2000 traps this means 400-500

replacements every year.”

Power Magazine

April 1980

“The average disc trap should last six months

to a year...disc traps sometimes failed ‘with-

in days of installation’...”

Energy User news

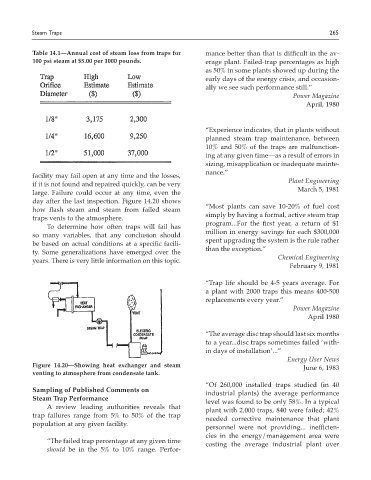

Figure 14.20—Showing heat exchanger and steam

June 6, 1983

venting to atmosphere from condensate tank.

“Of 260,000 installed traps studied (in 40

Sampling of Published Comments on

industrial plants) the average performance

Steam Trap Performance

level was found to be only 58%. In a typical

A review leading authorities reveals that

plant with 2,000 traps, 840 were failed; 42%

trap failures range from 5% to 50% of the trap

needed corrective maintenance that plant

population at any given facility.

personnel were not providing... inefficien-

cies in the energy/management area were

“The failed trap percentage at any given time

costing the average industrial plant over

should be in the 5% to 10% range. Perfor-