Page 279 - Boiler plant and distribution system optimization manual

P. 279

264 Boiler Plant and Distribution System Optimization Manual

the seat. This opens the trap and it begins the cy- reaches the trap, the element warms and changes

cle again. shape, exerting a closing force on the valve.

Reduced temperature from a steam and non-

condensible gas mixture will also cool the bellows Expansive Element Steam Traps

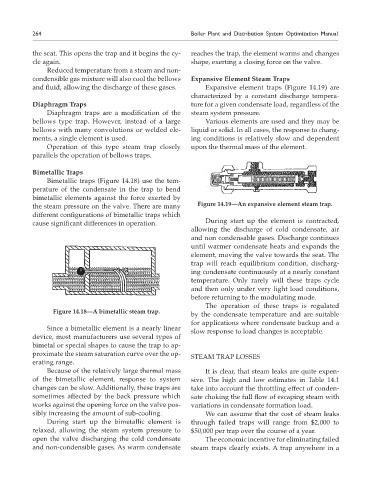

and fluid, allowing the discharge of these gases. Expansive element traps (Figure 14.19) are

characterized by a constant discharge tempera-

Diaphragm Traps ture for a given condensate load, regardless of the

Diaphragm traps are a modification of the steam system pressure.

bellows type trap. However, instead of a large Various elements are used and they may be

bellows with many convolutions or welded ele- liquid or solid. In all cases, the response to chang-

ments, a single element is used. ing conditions is relatively slow and dependent

Operation of this type steam trap closely upon the thermal mass of the element.

parallels the operation of bellows traps.

Bimetallic Traps

Bimetallic traps (Figure 14.18) use the tem-

perature of the condensate in the trap to bend

bimetallic elements against the force exerted by

the steam pressure on the valve. There are many Figure 14.19—An expansive element steam trap.

different configurations of bimetallic traps which

cause significant differences in operation. During start up the element is contracted,

allowing the discharge of cold condensate, air

and non condensable gases. Discharge continues

until warmer condensate heats and expands the

element, moving the valve towards the seat. The

trap will reach equilibrium condition, discharg-

ing condensate continuously at a nearly constant

temperature. Only rarely will these traps cycle

and then only under very light load conditions,

before returning to the modulating mode.

The operation of these traps is regulated

Figure 14.18—A bimetallic steam trap.

by the condensate temperature and are suitable

for applications where condensate backup and a

Since a bimetallic element is a nearly linear

slow response to load changes is acceptable.

device, most manufacturers use several types of

bimetal or special shapes to cause the trap to ap-

proximate the steam saturation curve over the op-

STEAM TRAP LOSSES

erating range.

Because of the relatively large thermal mass It is clear, that steam leaks are quite expen-

of the bimetallic element, response to system sive. The high and low estimates in Table 14.1

changes can be slow. Additionally, these traps are take into account the throttling effect of conden-

sometimes affected by the back pressure which sate choking the full flow of escaping steam with

works against the opening force on the valve pos- variations in condensate formation load.

sibly increasing the amount of sub-cooling. We can assume that the cost of steam leaks

During start up the bimetallic element is through failed traps will range from $2,000 to

relaxed, allowing the steam system pressure to $50,000 per trap over the course of a year.

open the valve discharging the cold condensate The economic incentive for eliminating failed

and non-condensible gases. As warm condensate steam traps clearly exists. A trap anywhere in a