Page 53 - Boiler plant and distribution system optimization manual

P. 53

38 Boiler Plant and Distribution System Optimization Manual

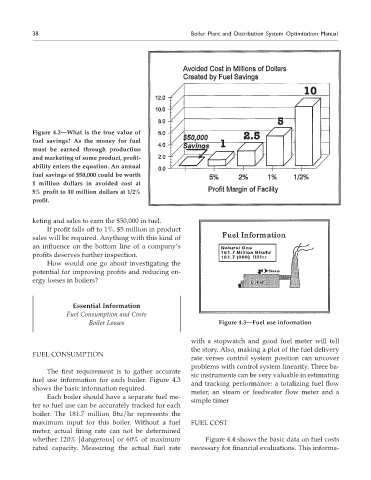

Figure 4.2—What is the true value of

fuel savings? As the money for fuel

must be earned through production

and marketing of some product, profit-

ability enters the equation. An annual

fuel savings of $50,000 could be worth

1 million dollars in avoided cost at

5% profit to 10 million dollars at 1/2%

profit.

keting and sales to earn the $50,000 in fuel.

If profit falls off to 1%, $5 million in product

sales will be required. Anything with this kind of

an influence on the bottom line of a company’s

profits deserves further inspection.

How would one go about investigating the

potential for improving profits and reducing en-

ergy losses in boilers?

Essential Information

Fuel Consumption and Costs

Boiler Losses Figure 4.3—Fuel use information

with a stopwatch and good fuel meter will tell

the story. Also, making a plot of the fuel delivery

FUEL CONSUMPTION

rate verses control system position can uncover

problems with control system linearity. Three ba-

The first requirement is to gather accurate

sic instruments can be very valuable in estimating

fuel use information for each boiler. Figure 4.3

and tracking performance: a totalizing fuel flow

shows the basic information required.

meter, an steam or feedwater flow meter and a

Each boiler should have a separate fuel me-

simple timer

ter so fuel use can be accurately tracked for each

boiler. The 181.7 million Btu/hr represents the

maximum input for this boiler. Without a fuel FUEL COST

meter, actual firing rate can not be determined

whether 120% [dangerous] or 60% of maximum Figure 4.4 shows the basic data on fuel costs

rated capacity. Measuring the actual fuel rate necessary for financial evaluations. This informa-