Page 57 - Boiler plant and distribution system optimization manual

P. 57

42 Boiler Plant and Distribution System Optimization Manual

TUNE-UP

Sources of Air Fuel Ratio Errors

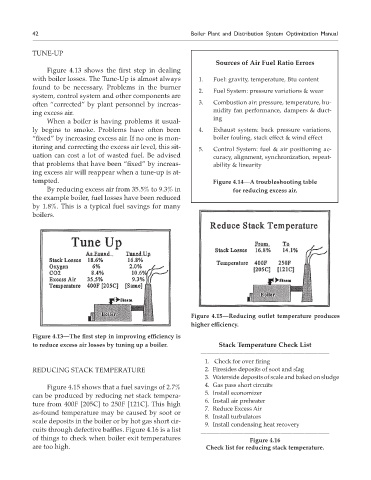

Figure 4.13 shows the first step in dealing

with boiler losses. The Tune-Up is almost always 1. Fuel: gravity, temperature, Btu content

found to be necessary. Problems in the burner

2. Fuel System: pressure variations & wear

system, control system and other components are

often “corrected” by plant personnel by increas- 3. Combustion air: pressure, temperature, hu-

midity fan performance, dampers & duct-

ing excess air.

ing

When a boiler is having problems it usual-

ly begins to smoke. Problems have often been 4. Exhaust system: back pressure variations,

“fixed” by increasing excess air. If no one is mon- boiler fouling, stack effect & wind effect

itoring and correcting the excess air level, this sit- 5. Control System: fuel & air positioning ac-

uation can cost a lot of wasted fuel. Be advised curacy, alignment, synchronization, repeat-

that problems that have been “fixed” by increas- ability & linearity

ing excess air will reappear when a tune-up is at-

tempted. Figure 4.14—A troubleshooting table

By reducing excess air from 35.5% to 9.3% in for reducing excess air.

the example boiler, fuel losses have been reduced

by 1.8%. This is a typical fuel savings for many

boilers.

Figure 4.15—Reducing outlet temperature produces

higher efficiency.

Figure 4.13—The first step in improving efficiency is

to reduce excess air losses by tuning up a boiler. Stack Temperature Check List

—————————————————————

1. Check for over firing

REDUCING STACK TEMPERATURE 2. Firesides deposits of soot and slag

3. Waterside deposits of scale and baked on sludge

Figure 4.15 shows that a fuel savings of 2.7% 4. Gas pass short circuits

5. Install economizer

can be produced by reducing net stack tempera-

6. Install air preheater

ture from 400F [205C] to 250F [121C]. This high

7. Reduce Excess Air

as-found temperature may be caused by soot or

8. Install turbulators

scale deposits in the boiler or by hot gas short cir-

9. Install condensing heat recovery

cuits through defective baffles. Figure 4.16 is a list

—————————————————————

of things to check when boiler exit temperatures Figure 4.16

are too high. Check list for reducing stack temperature.