Page 55 - Boiler plant and distribution system optimization manual

P. 55

40 Boiler Plant and Distribution System Optimization Manual

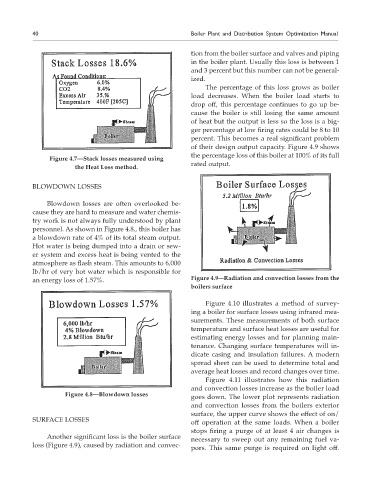

tion from the boiler surface and valves and piping

in the boiler plant. Usually this loss is between 1

and 3 percent but this number can not be general-

ized.

The percentage of this loss grows as boiler

load decreases. When the boiler load starts to

drop off, this percentage continues to go up be-

cause the boiler is still losing the same amount

of heat but the output is less so the loss is a big-

ger percentage at low firing rates could be 8 to 10

percent. This becomes a real significant problem

of their design output capacity. Figure 4.9 shows

the percentage loss of this boiler at 100% of its full

Figure 4.7—Stack losses measured using

rated output.

the Heat Loss method.

BLOWDOWN LOSSES

Blowdown losses are often overlooked be-

cause they are hard to measure and water chemis-

try work is not always fully understood by plant

personnel. As shown in Figure 4.8., this boiler has

a blowdown rate of 4% of its total steam output.

Hot water is being dumped into a drain or sew-

er system and excess heat is being vented to the

atmosphere as flash steam. This amounts to 6,000

lb/hr of very hot water which is responsible for

an energy loss of 1.57%. Figure 4.9—Radiation and convection losses from the

boilers surface

Figure 4.10 illustrates a method of survey-

ing a boiler for surface losses using infrared mea-

surements. These measurements of both surface

temperature and surface heat losses are useful for

estimating energy losses and for planning main-

tenance. Changing surface temperatures will in-

dicate casing and insulation failures. A modern

spread sheet can be used to determine total and

average heat losses and record changes over time.

Figure 4.11 illustrates how this radiation

and convection losses increase as the boiler load

Figure 4.8—Blowdown losses

goes down. The lower plot represents radiation

and convection losses from the boilers exterior

surface, the upper curve shows the effect of on/

SURFACE LOSSES

off operation at the same loads. When a boiler

stops firing a purge of at least 4 air changes is

Another significant loss is the boiler surface

necessary to sweep out any remaining fuel va-

loss (Figure 4.9), caused by radiation and convec-

pors. This same purge is required on light off.