Page 54 - Boiler plant and distribution system optimization manual

P. 54

Basic Boiler Plant Efficiency 39

tion is important for the analysis of dollar losses

and for evaluating the dollar value of fuel saving

opportunities. The $727 per hour represents the

maximum firing rate.

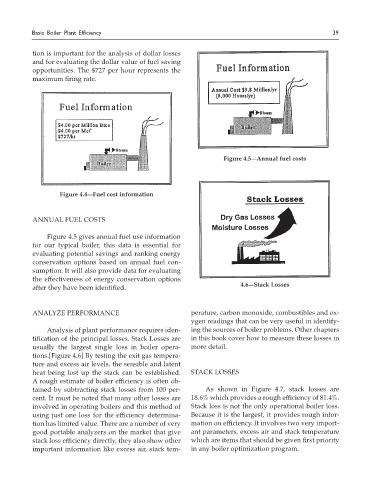

Figure 4.5—Annual fuel costs

Figure 4.4—Fuel cost information

ANNUAL FUEL COSTS

Figure 4.5 gives annual fuel use information

for our typical boiler, this data is essential for

evaluating potential savings and ranking energy

conservation options based on annual fuel con-

sumption. It will also provide data for evaluating

the effectiveness of energy conservation options

4.6—Stack Losses

after they have been identified.

ANALYzE PERFORMANCE perature, carbon monoxide, combustibles and ox-

ygen readings that can be very useful in identify-

Analysis of plant performance requires iden- ing the sources of boiler problems. Other chapters

tification of the principal losses. Stack Losses are in this book cover how to measure these losses in

usually the largest single loss in boiler opera- more detail.

tions.[Figure 4.6] By testing the exit gas tempera-

ture and excess air levels, the sensible and latent

heat being lost up the stack can be established. STACK LOSSES

A rough estimate of boiler efficiency is often ob-

tained by subtracting stack losses from 100 per- As shown in Figure 4.7, stack losses are

cent. It must be noted that many other losses are 18.6% which provides a rough efficiency of 81.4%.

involved in operating boilers and this method of Stack loss is not the only operational boiler loss.

using just one loss for the efficiency determina- Because it is the largest, it provides rough infor-

tion has limited value. There are a number of very mation on efficiency. It involves two very import-

good portable analyzers on the market that give ant parameters, excess air and stack temperature

stack loss efficiency directly, they also show other which are items that should be given first priority

important information like excess air, stack tem- in any boiler optimization program.