Page 75 - CNC Robotics

P. 75

,--------------------------~--

CNC Robotics

APPLICATION NOTE

bridge transist~rs will be forward biased by the

In general the best performance, in terms of

torque, is achieved using the chopping current ~ransformer action of the motor windings , provid-

control technique [2]. This technique also allows In9 an effective short circuit across the supply.

easy implementation of multiple current level Secondlythe L298N , even though it has split sup-

drive techniques to improve the motor perform- ply voltages , may not be used without a high volt-

ance. [1] age supply on the chip since a portion of the drive

current for the output bridge is derived from this

supply .

Driving a Unipolar Motor with the l 298N or

L6202

Selecti ng Enable or Pha se chopping

Although it is not the optimal solution, design con-

straints sometimes limit the motor selection, In Whe!1 implementing chopping control of the cur-

t~e ca~e where the designer is looking for a rent In a stepper motor , there are several ways in

highly Integrated driv~ stage ~ith improved per- which the current control can be implemented. A

formance over previous des igns but is con- bridqe output, like the L6202 or L298N, may be

strained to d~ive a unipolar wound (6 leaded) mo- driven In enable choppinq, one phase chopping or

to~ It IS possible to drive the motor with H-Briclge two p~ase chopping , as shown in Figure 6. The

drivers like the l298N or L6202. To drive such a L297 I,mplements enable chopping or one phase

motor the center tap of the motor should be left choPPII:'!g, selected by the control input. The

unconnected and the two ends of the common L6506 Implements one phase chopping, with the

winding,s ar~ connected to the ~ridge outputs, as recirculation path around the lower half of the

show n In Figure 5. In this configuration the user bridge , if the four outputs are connected to the 4

should notice a marked improvement in torque for inputs of the bridge or enable chopping if the odd

numbered outputs are connected to the enable

the same coil current, or put another way, the

same torque output will be achieved with a lower inputs of the bridge . Selecting the correct chop-

coil current. ping mode is an important consideration that af-

fects the stability of the system as well as the dis-

A solution where the L298N or L6202 is used to sipatio n. Table 1 shows a relative comparison of

drive a unipolar motor while keeping the center the different chopping modes, for a fixed chop-

c,?nnection of each coil connected to the supply ping frequency, motor current and motor induc-

Will not work. First, the protection diodes needed tance .

from collector to emitter (drain to source) of the

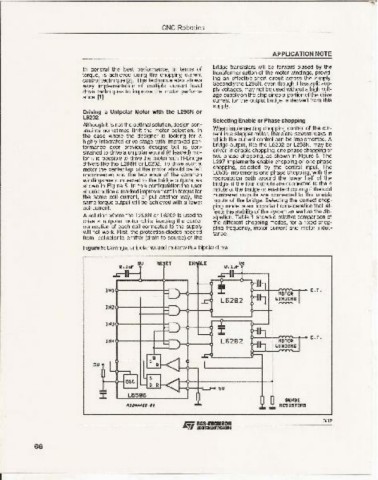

Figu re 5: Driving a unipolar wound motor with a bipolar drive

U

50 RESET ENABLE B.1UFvT~

,;,'~-:r ...-I: I

--< HI-,

I H, ~ MOTORT C. T.

-i HI-,

1.,.;-< L62eJ2 rwlHDING

IH2

>=I

IH3 1:-

H ~

'----<

I H. L62eJ2 MOTORT C. T.

:3 ... .....1-] UINDING

eJ-< >-

5U

~ I • L

B'~-:I 5U

•

Q

:f L6596 .....

SENSE

1I!13111U.,·.1 . 1. .-. ~ RESI STORS

3/12

66

, - - - - - - - - - - - - - - - - - - - - -