Page 552 - Cam Design Handbook

P. 552

THB16 9/19/03 8:04 PM Page 540

540 CAM DESIGN HANDBOOK

0.050

0.045

0.040

0.035

Thousandths inches 0.030

0.025

0.020

0.015

0.010

0.005

7000 7500 8000 8500 9000 9500

APM

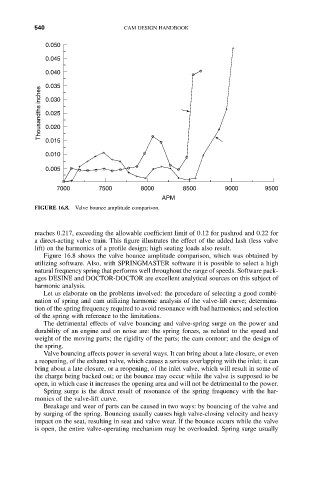

FIGURE 16.8. Valve bounce amplitude comparison.

reaches 0.217, exceeding the allowable coefficient limit of 0.12 for pushrod and 0.22 for

a direct-acting valve train. This figure illustrates the effect of the added lash (less valve

lift) on the harmonics of a profile design; high seating loads also result.

Figure 16.8 shows the valve bounce amplitude comparison, which was obtained by

utilizing software. Also, with SPRINGMASTER software it is possible to select a high

natural frequency spring that performs well throughout the range of speeds. Software pack-

ages DESINE and DOCTOR-DOCTOR are excellent analytical sources on this subject of

harmonic analysis.

Let us elaborate on the problems involved: the procedure of selecting a good combi-

nation of spring and cam utilizing harmonic analysis of the valve-lift curve; determina-

tion of the spring frequency required to avoid resonance with bad harmonics; and selection

of the spring with reference to the limitations.

The detrimental effects of valve bouncing and valve-spring surge on the power and

durability of an engine and on noise are: the spring forces, as related to the speed and

weight of the moving parts; the rigidity of the parts; the cam contour; and the design of

the spring.

Valve bouncing affects power in several ways. It can bring about a late closure, or even

a reopening, of the exhaust valve, which causes a serious overlapping with the inlet; it can

bring about a late closure, or a reopening, of the inlet valve, which will result in some of

the charge being backed out; or the bounce may occur while the valve is supposed to be

open, in which case it increases the opening area and will not be detrimental to the power.

Spring surge is the direct result of resonance of the spring frequency with the har-

monics of the valve-lift curve.

Breakage and wear of parts can be caused in two ways: by bouncing of the valve and

by surging of the spring. Bouncing usually causes high valve-closing velocity and heavy

impact on the seat, resulting in seat and valve wear. If the bounce occurs while the valve

is open, the entire valve-operating mechanism may be overloaded. Spring surge usually