Page 132 - Carbon Nanotube Fibres and Yarns

P. 132

124 Carbon Nanotube Fibers and Yarns

(A) 50µm (D) 50µm

(B) 5µm (E) 5µm

Pores

CNT fiber direction CNT fiber direction

(C) 2µm (F) 2µm

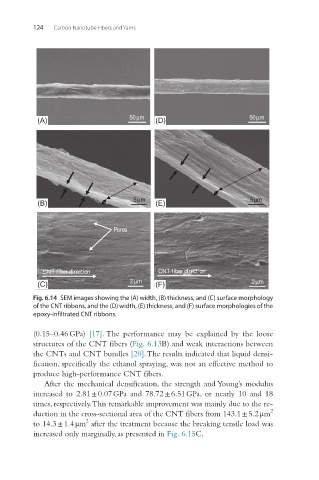

Fig. 6.14 SEM images showing the (A) width, (B) thickness, and (C) surface morphology

of the CNT ribbons, and the (D) width, (E) thickness, and (F) surface morphologies of the

epoxy-infiltrated CNT ribbons.

(0.15–0.46 GPa) [17]. The performance may be explained by the loose

structures of the CNT fibers (Fig. 6.13B) and weak interactions between

the CNTs and CNT bundles [20]. The results indicated that liquid densi-

fication, specifically the ethanol spraying, was not an effective method to

produce high-performance CNT fibers.

After the mechanical densification, the strength and Young’s modulus

increased to 2.81 ± 0.07 GPa and 78.72 ± 6.51 GPa, or nearly 10 and 18

times, respectively. This remarkable improvement was mainly due to the re-

2

duction in the cross-sectional area of the CNT fibers from 143.1 ± 5.2 μm

2

to 14.3 ± 1.4 μm after the treatment because the breaking tensile load was

increased only marginally, as presented in Fig. 6.15C.