Page 242 - Carbon Nanotube Fibres and Yarns

P. 242

232 Carbon Nanotube Fibers and Yarns

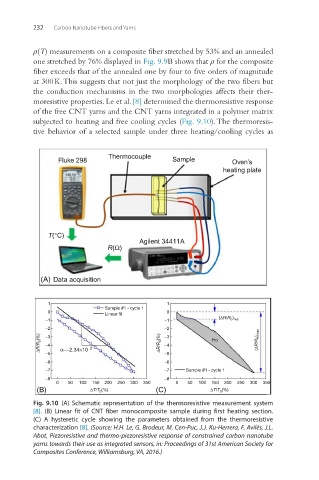

ρ(T) measurements on a composite fiber stretched by 53% and an annealed

one stretched by 76% displayed in Fig. 9.9B shows that ρ for the composite

fiber exceeds that of the annealed one by four to five orders of magnitude

at 300 K. This suggests that not just the morphology of the two fibers but

the conduction mechanisms in the two morphologies affects their ther-

moresistive properties. Le et al. [8] determined the thermoresistive response

of the free CNT yarns and the CNT yarns integrated in a polymer matrix

subjected to heating and free cooling cycles (Fig. 9.10). The thermoresis-

tive behavior of a selected sample under three heating/cooling cycles as

Thermocouple

Fluke 298 Sample Oven’s

heating plate

T(°C)

Agilent 34411A

R(Ω)

(A) Data acquisition

1 1

Sample #1 - cycle 1

0 Linear fit 0

−1 −1 (∆R/R 0 ) res

−2 −2

∆R/R 0 (%) −3 −2 ∆R/R 0(%) −3 Hα (∆R/R 0 ) max

−4

−4

−5 α∼−2.34×10 −5

−6 −6

−7 −7 Sample #1 - cycle 1

−8 −8

0 50 100 150 200 250 300 350 0 50 100 150 200 250 300 350

(B) ∆T/T 0 (%) (C) ∆T/T 0 (%)

Fig. 9.10 (A) Schematic representation of the thermoresistive measurement system

[8]. (B) Linear fit of CNT fiber monocomposite sample during first heating section.

(C) A hysteretic cycle showing the parameters obtained from the thermoresistive

characterization [8]. (Source: H.H. Le, G. Brodeur, M. Cen-Puc, J.J. Ku-Herrera, F. Avilés, J.L.

Abot, Piezoresistive and thermo-piezoresistive response of constrained carbon nanotube

yarns towards their use as integrated sensors, in: Proceedings of 31st American Society for

Composites Conference, Williamsburg, VA, 2016.)