Page 243 - Carbon Nanotube Fibres and Yarns

P. 243

Sensors based on CNT yarns 233

shown in Fig. 9.10 shows a negative thermoresistive coefficient, that is,

R decreases with increasing temperature like earlier reports. However, the

transition behavior was not seen in the R-T curve even up to 300 K as seen

in Fig. 9.10C. This indicates that some molecular rearrangement and pos-

sibly tunneling could be happening during the heating and cooling cycles

that affect the thermoresistivity. Further studies are needed to fully explain

this behavior.

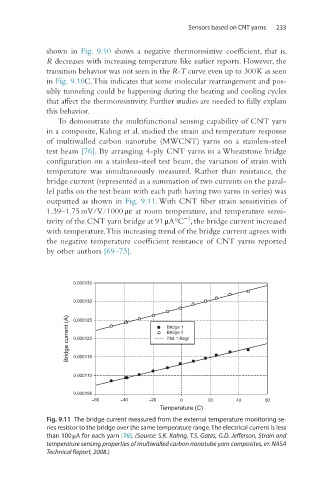

To demonstrate the multifunctional sensing capability of CNT yarn

in a composite, Kahng et al. studied the strain and temperature response

of multiwalled carbon nanotube (MWCNT) yarns on a stainless-steel

test beam [76]. By arranging 4-ply CNT yarns in a Wheatstone bridge

configuration on a stainless-steel test beam, the variation of strain with

temperature was simultaneously measured. Rather than resistance, the

bridge current (represented as a summation of two currents on the paral-

lel paths on the test beam with each path having two yarns in series) was

outputted as shown in Fig. 9.11. With CNT fiber strain sensitivities of

1.39–1.75 mV/V/1000 με at room temperature, and temperature sensi-

−1

tivity of the CNT yarn bridge at 91 μA°C , the bridge current increased

with temperature. This increasing trend of the bridge current agrees with

the negative temperature coefficient resistance of CNT yarns reported

by other authors [69–73].

0.000135

0.000130

Bridge current (A) 0.000120 Bridge 1

0.000125

Bridge 2

Plot 1 Regr

0.000115

0.000110

0.000105

−60 −40 −20 0 20 40 60

Temperature (C)

Fig. 9.11 The bridge current measured from the external temperature monitoring se-

ries resistor to the bridge over the same temperature range. The electrical current is less

than 100 μA for each yarn [76]. (Source: S.K. Kahng, T.S. Gates, G.D. Jefferson, Strain and

temperature sensing properties of multiwalled carbon nanotube yarn composites, in: NASA

Technical Report, 2008.)