Page 147 - Carrahers_Polymer_Chemistry,_Eighth_Edition

P. 147

110 Carraher’s Polymer Chemistry

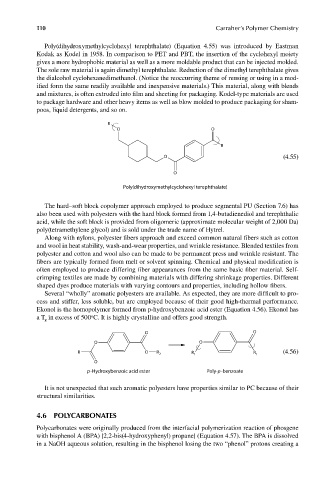

Poly(dihydroxymethylcyclohexyl terephthalate) (Equation 4.55) was introduced by Eastman

Kodak as Kodel in 1958. In comparison to PET and PBT, the insertion of the cyclohexyl moiety

gives a more hydrophobic material as well as a more moldable product that can be injected molded.

The sole raw material is again dimethyl terephthalate. Reduction of the dimethyl terephthalate gives

the dialcohol cyclohexanedimethanol. (Notice the reoccurring theme of reusing or using in a mod-

ified form the same readily available and inexpensive materials.) This material, along with blends

and mixtures, is often extruded into film and sheeting for packaging. Kodel-type materials are used

to package hardware and other heavy items as well as blow molded to produce packaging for sham-

poos, liquid detergents, and so on.

R

O O

R

O (4.55)

O

Poly(dihydroxymethylcyclohexyl terephthalate)

The hard–soft block copolymer approach employed to produce segmental PU (Section 7.6) has

also been used with polyesters with the hard block formed from 1,4-butadienediol and terephthalic

acid, while the soft block is provided from oligomeric (approximate molecular weight of 2,000 Da)

poly(tetramethylene glycol) and is sold under the trade name of Hytrel.

Along with nylons, polyester fibers approach and exceed common natural fibers such as cotton

and wool in heat stability, wash-and-wear properties, and wrinkle resistance. Blended textiles from

polyester and cotton and wool also can be made to be permanent press and wrinkle resistant. The

fibers are typically formed from melt or solvent spinning. Chemical and physical modifi cation is

often employed to produce differing fiber appearances from the same basic fiber material. Self-

crimping textiles are made by combining materials with differing shrinkage properties. Different

shaped dyes produce materials with varying contours and properties, including hollow fi bers.

Several “wholly” aromatic polyesters are available. As expected, they are more diffi cult to pro-

cess and stiffer, less soluble, but are employed because of their good high-thermal performance.

Ekonol is the homopolymer formed from p-hydroxybenzoic acid ester (Equation 4.56). Ekonol has

o

a T in excess of 500 C. It is highly crystalline and offers good strength.

g

O O

O O

R O R 2 R 1 R 1 (4.56)

O

p -Hydroxybenzoic acid ester Poly-p -benzoate

It is not unexpected that such aromatic polyesters have properties similar to PC because of their

structural similarities.

4.6 POLYCARBONATES

Polycarbonates were originally produced from the interfacial polymerization reaction of phosgene

with bisphenol A (BPA) [2,2-bis(4-hydroxyphenyl) propane] (Equation 4.57). The BPA is dissolved

in a NaOH aqueous solution, resulting in the bisphenol losing the two “phenol” protons creating a

9/14/2010 3:38:20 PM

K10478.indb 110 9/14/2010 3:38:20 PM

K10478.indb 110