Page 158 - Carrahers_Polymer_Chemistry,_Eighth_Edition

P. 158

Polycondensation Polymers 121

4.9 POLYBENZIMIDAZOLES AND RELATED POLYMERS

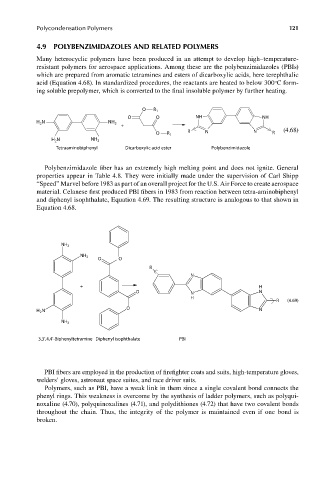

Many heterocyclic polymers have been produced in an attempt to develop high–temperature-

resistant polymers for aerospace applications. Among these are the polybenzimidazoles (PBIs)

which are prepared from aromatic tetramines and esters of dicarboxylic acids, here terephthalic

o

acid (Equation 4.68). In standardized procedures, the reactants are heated to below 300 C form-

ing soluble prepolymer, which is converted to the final insoluble polymer by further heating.

O R 1

O O NH NH

H 2 N NH 2

+

O R 1 R N N R (4.68)

H 2 N NH 2

Tetraaminobiphenyl Dicarboxylic acid ester Polybenzimidazole

Polybenzimidazole fiber has an extremely high melting point and does not ignite. General

properties appear in Table 4.8. They were initially made under the supervision of Carl Shipp

“Speed” Marvel before 1983 as part of an overall project for the U.S. Air Force to create aerospace

material. Celanese first produced PBI fibers in 1983 from reaction between tetra-aminobiphenyl

and diphenyl isophthalate, Equation 4.69. The resulting structure is analogous to that shown in

Equation 4.68.

NH 2

NH 2

O O

R

N

+ H

O N N

H

R (4.69)

O N

HN

2

NH 2

3,3’,4,4’-Biphenyltetramine Diphenyl isophthalate PBI

PBI fibers are employed in the production of fi refighter coats and suits, high-temperature gloves,

welders’ gloves, astronaut space suites, and race driver suits.

Polymers, such as PBI, have a weak link in them since a single covalent bond connects the

phenyl rings. This weakness is overcome by the synthesis of ladder polymers, such as polyqui-

noxaline (4.70), polyquinoxalines (4.71), and polydithiones (4.72) that have two covalent bonds

throughout the chain. Thus, the integrity of the polymer is maintained even if one bond is

broken.

9/14/2010 3:38:24 PM

K10478.indb 121 9/14/2010 3:38:24 PM

K10478.indb 121