Page 159 - Carrahers_Polymer_Chemistry,_Eighth_Edition

P. 159

122 Carraher’s Polymer Chemistry

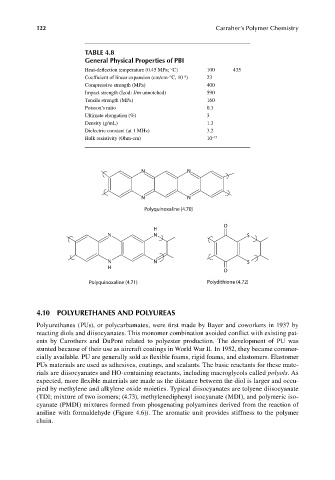

TABLE 4.8

General Physical Properties of PBI

Heat-deflection temperature (0.45 MPa; °C) 100 435

–6

Coefficient of linear expansion (cm/cm-°C, 10 ) 23

Compressive strength (MPa) 400

Impact strength (Izod: J/m unnotched) 590

Tensile strength (MPa) 160

Poisson’s ratio 0.3

Ultimate elongation (%) 3

Density (g/mL) 1.3

Dielectric constant (at 1 MHz) 3.2

Bulk resistivity (Ohm-cm) 10 –15

N N

N N

Polyquinoxaline (4.70)

O

H

N N S

N N S

H

O

Polyquinoxaline (4.71) Polydithione (4.72)

4.10 POLYURETHANES AND POLYUREAS

Polyurethanes (PUs), or polycarbamates, were first made by Bayer and coworkers in 1937 by

reacting diols and diisocyanates. This monomer combination avoided conflict with existing pat-

ents by Carothers and DuPont related to polyester production. The development of PU was

stunted because of their use as aircraft coatings in World War II. In 1952, they became commer-

cially available. PU are generally sold as flexible foams, rigid foams, and elastomers. Elastomer

PUs materials are used as adhesives, coatings, and sealants. The basic reactants for these mate-

rials are diisocyanates and HO-containing reactants, including macroglycols called polyols. As

expected, more fl exible materials are made as the distance between the diol is larger and occu-

pied by methylene and alkylene oxide moieties. Typical diisocyanates are tolyene diisocyanate

(TDI; mixture of two isomers; (4.73), methylenediphenyl isocyanate (MDI), and polymeric iso-

cyanate (PMDI) mixtures formed from phosgenating polyamines derived from the reaction of

aniline with formaldehyde (Figure 4.6)). The aromatic unit provides stiffness to the polymer

chain.

9/14/2010 3:38:25 PM

K10478.indb 122

K10478.indb 122 9/14/2010 3:38:25 PM