Page 604 - Carrahers_Polymer_Chemistry,_Eighth_Edition

P. 604

Synthesis of Reactants and Intermediates for Polymers 567

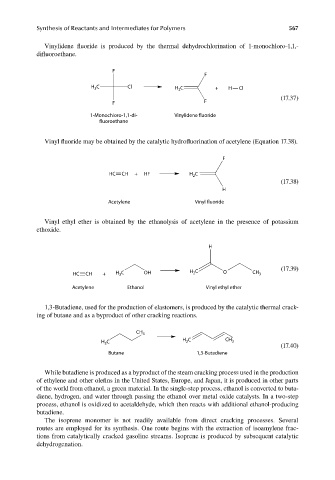

Vinylidene fluoride is produced by the thermal dehydrochlorination of 1-monochloro-1,1,-

difl uoroethane.

F

F

H C Cl H C + H Cl

3

2

(17.37)

F F

1-Monochloro-1,1-di- Vinylidene fluoride

fluoroethane

Vinyl fluoride may be obtained by the catalytic hydrofluorination of acetylene (Equation 17.38).

F

HC CH + HF H C

2

(17.38)

H

Acetylene Vinyl fluoride

Vinyl ethyl ether is obtained by the ethanolysis of acetylene in the presence of potassium

ethoxide.

H

(17.39)

H C

HC CH + H C OH 2 O CH 3

3

Acetylene Ethanol Vinyl ethyl ether

1,3-Butadiene, used for the production of elastomers, is produced by the catalytic thermal crack-

ing of butane and as a byproduct of other cracking reactions.

CH 3

H C

H C 2 CH 3

3

(17.40)

Butane 1,3-Butadiene

While butadiene is produced as a byproduct of the steam cracking process used in the production

of ethylene and other olefi ns in the United States, Europe, and Japan, it is produced in other parts

of the world from ethanol, a green material. In the single-step process, ethanol is converted to buta-

diene, hydrogen, and water through passing the ethanol over metal oxide catalysts. In a two-step

process, ethanol is oxidized to acetaldehyde, which then reacts with additional ethanol-producing

butadiene.

The isoprene monomer is not readily available from direct cracking processes. Several

routes are employed for its synthesis. One route begins with the extraction of isoamylene frac-

tions from catalytically cracked gasoline streams. Isoprene is produced by subsequent catalytic

dehydrogenation.

9/14/2010 3:43:29 PM

K10478.indb 567

K10478.indb 567 9/14/2010 3:43:29 PM