Page 106 - Chalcogenide Glasses for Infrared Optics

P. 106

84 Cha pte r T h ree

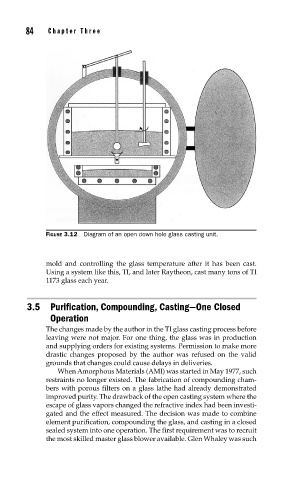

FIGURE 3.12 Diagram of an open down hole glass casting unit.

mold and controlling the glass temperature after it has been cast.

Using a system like this, TI, and later Raytheon, cast many tons of TI

1173 glass each year.

3.5 Purification, Compounding, Casting—One Closed

Operation

The changes made by the author in the TI glass casting process before

leaving were not major. For one thing, the glass was in production

and supplying orders for existing systems. Permission to make more

drastic changes proposed by the author was refused on the valid

grounds that changes could cause delays in deliveries.

When Amorphous Materials (AMI) was started in May 1977, such

restraints no longer existed. The fabrication of compounding cham-

bers with porous filters on a glass lathe had already demonstrated

improved purity. The drawback of the open casting system where the

escape of glass vapors changed the refractive index had been investi-

gated and the effect measured. The decision was made to combine

element purification, compounding the glass, and casting in a closed

sealed system into one operation. The first requirement was to recruit

the most skilled master glass blower available. Glen Whaley was such