Page 107 - Chalcogenide Glasses for Infrared Optics

P. 107

Glass Pr oduction 85

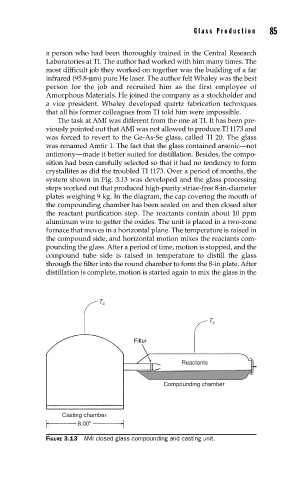

a person who had been thoroughly trained in the Central Research

Laboratories at TI. The author had worked with him many times. The

most difficult job they worked on together was the building of a far

infrared (95.8-µm) pure He laser. The author felt Whaley was the best

person for the job and recruited him as the first employee of

Amorphous Materials. He joined the company as a stockholder and

a vice president. Whaley developed quartz fabrication techniques

that all his former colleagues from TI told him were impossible.

The task at AMI was different from the one at TI. It has been pre-

viously pointed out that AMI was not allowed to produce TI 1173 and

was forced to revert to the Ge-As-Se glass, called TI 20. The glass

was renamed Amtir 1. The fact that the glass contained arsenic—not

antimony—made it better suited for distillation. Besides, the compo-

sition had been carefully selected so that it had no tendency to form

crystallites as did the troubled TI 1173. Over a period of months, the

system shown in Fig. 3.13 was developed and the glass processing

steps worked out that produced high-purity striae-free 8-in-diameter

plates weighing 9 kg. In the diagram, the cap covering the mouth of

the compounding chamber has been sealed on and then closed after

the reactant purification step. The reactants contain about 10 ppm

aluminum wire to getter the oxides. The unit is placed in a two-zone

furnace that moves in a horizontal plane. The temperature is raised in

the compound side, and horizontal motion mixes the reactants com-

pounding the glass. After a period of time, motion is stopped, and the

compound tube side is raised in temperature to distill the glass

through the filter into the round chamber to form the 8-in plate. After

distillation is complete, motion is started again to mix the glass in the

T c

T c

Filter

Reactants

Compounding chamber

Casting chamber

8.00"

FIGURE 3.13 AMI closed glass compounding and casting unit.