Page 105 - Chalcogenide Glasses for Infrared Optics

P. 105

Glass Pr oduction 83

10 ×

3

10 × Experimental data

2

Viscosity (p)

10 ×

1

Prior estimate

(extrapolated from 10 7.6

p & 10 4.7 p data points)

0

10 ×

500 600 700 800

Temperature (°C)

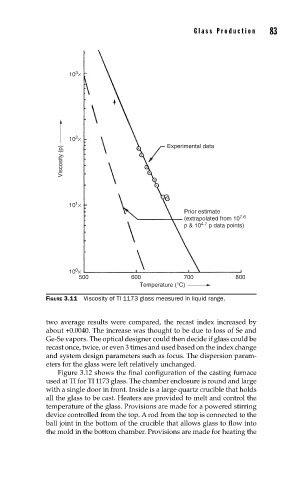

FIGURE 3.11 Viscosity of TI 1173 glass measured in liquid range.

two average results were compared, the recast index increased by

about +0.0040. The increase was thought to be due to loss of Se and

Ge-Se vapors. The optical designer could then decide if glass could be

recast once, twice, or even 3 times and used based on the index change

and system design parameters such as focus. The dispersion param-

eters for the glass were left relatively unchanged.

Figure 3.12 shows the final configuration of the casting furnace

used at TI for TI 1173 glass. The chamber enclosure is round and large

with a single door in front. Inside is a large quartz crucible that holds

all the glass to be cast. Heaters are provided to melt and control the

temperature of the glass. Provisions are made for a powered stirring

device controlled from the top. A rod from the top is connected to the

ball joint in the bottom of the crucible that allows glass to flow into

the mold in the bottom chamber. Provisions are made for heating the