Page 104 - Chalcogenide Glasses for Infrared Optics

P. 104

82 Cha pte r T h ree

Insulation

Heater control Equalization tube

thermocouple

Capillary

Heaters

Rotation Rotation

axis axis

Dip coil

Thermocouple #2

TI 1173 melt Thermocouple #1

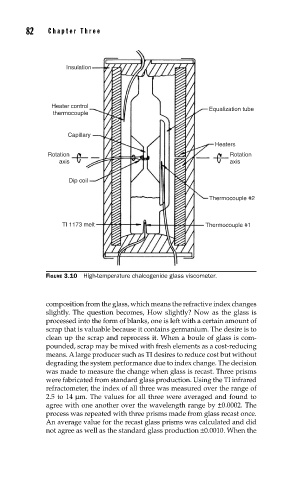

FIGURE 3.10 High-temperature chalcogenide glass viscometer.

composition from the glass, which means the refractive index changes

slightly. The question becomes, How slightly? Now as the glass is

processed into the form of blanks, one is left with a certain amount of

scrap that is valuable because it contains germanium. The desire is to

clean up the scrap and reprocess it. When a boule of glass is com-

pounded, scrap may be mixed with fresh elements as a cost-reducing

means. A large producer such as TI desires to reduce cost but without

degrading the system performance due to index change. The decision

was made to measure the change when glass is recast. Three prisms

were fabricated from standard glass production. Using the TI infrared

refractometer, the index of all three was measured over the range of

2.5 to 14 µm. The values for all three were averaged and found to

agree with one another over the wavelength range by ±0.0002. The

process was repeated with three prisms made from glass recast once.

An average value for the recast glass prisms was calculated and did

not agree as well as the standard glass production ±0.0010. When the