Page 99 - Chalcogenide Glasses for Infrared Optics

P. 99

Glass Pr oduction 77

to results from the standard production. Also shown are results of

absorption at 10.6 µm, determined by measuring the heat rise in a sample

while transmitting a CO laser beam of known intensity. The measure-

2

ment, termed laser calorimetry, was applied to the same glass by TI, the

Naval Research Laboratory, and the Catholic University. Results were

−1

from 0.012 to 0.007 cm . A correlation between Si content and absorp-

tion at 10.6 and 9.4 µm was found for both TI 1173 and TI 20. The

10.6-µm results are shown in Fig. 3.5. The X in the figure is for the one

TI 20 glass tested. Obviously, the reactant purification step would sub-

stantially improve quality and the transmission if adopted into the

production of these two infrared-transmitting chalcogenide glasses.

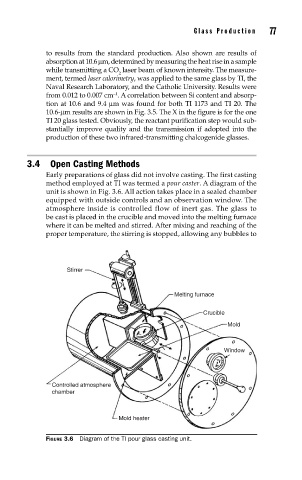

3.4 Open Casting Methods

Early preparations of glass did not involve casting. The first casting

method employed at TI was termed a pour caster. A diagram of the

unit is shown in Fig. 3.6. All action takes place in a sealed chamber

equipped with outside controls and an observation window. The

atmosphere inside is controlled flow of inert gas. The glass to

be cast is placed in the crucible and moved into the melting furnace

where it can be melted and stirred. After mixing and reaching of the

proper temperature, the stirring is stopped, allowing any bubbles to

Stirrer

Melting furnace

Crucible

Mold

Window

Controlled atmosphere

chamber

Mold heater

FIGURE 3.6 Diagram of the TI pour glass casting unit.