Page 128 - Chalcogenide Glasses for Infrared Optics

P. 128

Characterization of Glass Pr operties 105

Digital Par phase sensitive

voltmeter amplifier

Stepping motor

655, 360 steps/360°

Hg Cd Te

detector

Eason computer

control 1 step = 2

arc seconds

Optical 100

cycle

chopper

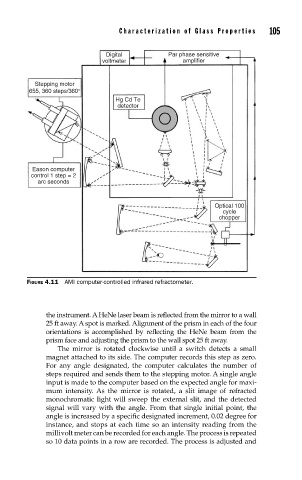

FIGURE 4.11 AMI computer-controlled infrared refractometer.

the instrument. A HeNe laser beam is reflected from the mirror to a wall

25 ft away. A spot is marked. Alignment of the prism in each of the four

orientations is accomplished by reflecting the HeNe beam from the

prism face and adjusting the prism to the wall spot 25 ft away.

The mirror is rotated clockwise until a switch detects a small

magnet attached to its side. The computer records this step as zero.

For any angle designated, the computer calculates the number of

steps required and sends them to the stepping motor. A single angle

input is made to the computer based on the expected angle for maxi-

mum intensity. As the mirror is rotated, a slit image of refracted

monochromatic light will sweep the external slit, and the detected

signal will vary with the angle. From that single initial point, the

angle is increased by a specific designated increment, 0.02 degree for

instance, and stops at each time so an intensity reading from the

millivolt meter can be recorded for each angle. The process is repeated

so 10 data points in a row are recorded. The process is adjusted and