Page 123 - Chalcogenide Glasses for Infrared Optics

P. 123

100 Cha pte r F o u r

M 2

Thermocouple leads

PE 301

To pump

Heat shield

∗

M 4

M 1

Optical wedge

NaCl plates

1st slit

∗ Sample dewar

30 seconds of

ARC indexing table M 5

2nd slit

Thermocouple detector

M 6

M 3

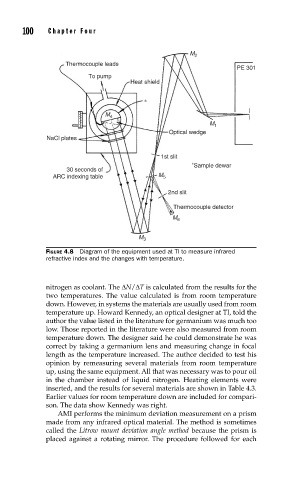

FIGURE 4.8 Diagram of the equipment used at TI to measure infrared

refractive index and the changes with temperature.

nitrogen as coolant. The ∆N/∆T is calculated from the results for the

two temperatures. The value calculated is from room temperature

down. However, in systems the materials are usually used from room

temperature up. Howard Kennedy, an optical designer at TI, told the

author the value listed in the literature for germanium was much too

low. Those reported in the literature were also measured from room

temperature down. The designer said he could demonstrate he was

correct by taking a germanium lens and measuring change in focal

length as the temperature increased. The author decided to test his

opinion by remeasuring several materials from room temperature

up, using the same equipment. All that was necessary was to pour oil

in the chamber instead of liquid nitrogen. Heating elements were

inserted, and the results for several materials are shown in Table 4.3.

Earlier values for room temperature down are included for compari-

son. The data show Kennedy was right.

AMI performs the minimum deviation measurement on a prism

made from any infrared optical material. The method is sometimes

called the Litrow mount deviation angle method because the prism is

placed against a rotating mirror. The procedure followed for each