Page 124 - Chalcogenide Glasses for Infrared Optics

P. 124

Characterization of Glass Pr operties 101

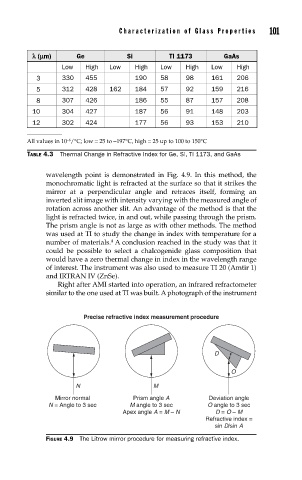

l (mm) Ge Si TI 1173 GaAs

Low High Low High Low High Low High

3 330 455 190 58 98 161 206

5 312 428 162 184 57 92 159 216

8 307 426 186 55 87 157 208

10 304 427 187 56 91 148 203

12 302 424 177 56 93 153 210

−6

All values in 10 /°C; low = 25 to −197°C, high = 25 up to 100 to 150°C

TABLE 4.3 Thermal Change in Refractive Index for Ge, Si, TI 1173, and GaAs

wavelength point is demonstrated in Fig. 4.9. In this method, the

monochromatic light is refracted at the surface so that it strikes the

mirror at a perpendicular angle and retraces itself, forming an

inverted slit image with intensity varying with the measured angle of

rotation across another slit. An advantage of the method is that the

light is refracted twice, in and out, while passing through the prism.

The prism angle is not as large as with other methods. The method

was used at TI to study the change in index with temperature for a

4

number of materials. A conclusion reached in the study was that it

could be possible to select a chalcogenide glass composition that

would have a zero thermal change in index in the wavelength range

of interest. The instrument was also used to measure TI 20 (Amtir 1)

and IRTRAN IV (ZnSe).

Right after AMI started into operation, an infrared refractometer

similar to the one used at TI was built. A photograph of the instrument

Precise refractive index measurement procedure

D

O

N M

Mirror normal Prism angle A Deviation angle

N = Angle to 3 sec M angle to 3 sec O angle to 3 sec

Apex angle A = M – N D = O – M

Refractive index =

sin D/sin A

FIGURE 4.9 The Litrow mirror procedure for measuring refractive index.