Page 239 - Chalcogenide Glasses for Infrared Optics

P. 239

AMI Infrar ed Crystalline Materials 215

CdTe strips

3"

2" Graphite

Graphite strip for end piece

Saw planes

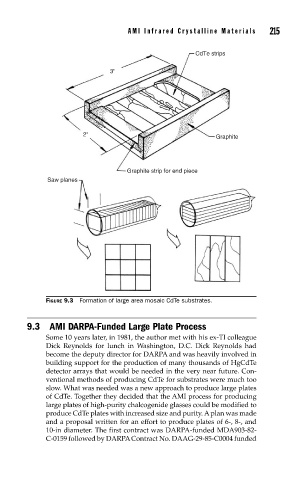

FIGURE 9.3 Formation of large area mosaic CdTe substrates.

9.3 AMI DARPA-Funded Large Plate Process

Some 10 years later, in 1981, the author met with his ex-TI colleague

Dick Reynolds for lunch in Washington, D.C. Dick Reynolds had

become the deputy director for DARPA and was heavily involved in

building support for the production of many thousands of HgCdTe

detector arrays that would be needed in the very near future. Con-

ventional methods of producing CdTe for substrates were much too

slow. What was needed was a new approach to produce large plates

of CdTe. Together they decided that the AMI process for producing

large plates of high-purity chalcogenide glasses could be modified to

produce CdTe plates with increased size and purity. A plan was made

and a proposal written for an effort to produce plates of 6-, 8-, and

10-in diameter. The first contract was DARPA-funded MDA903-82-

C-0159 followed by DARPA Contract No. DAAG-29-85-C0004 funded