Page 242 - Chalcogenide Glasses for Infrared Optics

P. 242

218 Cha pte r Ni ne

Cooling air

flow direction

Quartz wool

insulation

Outward from center Upward from bottom

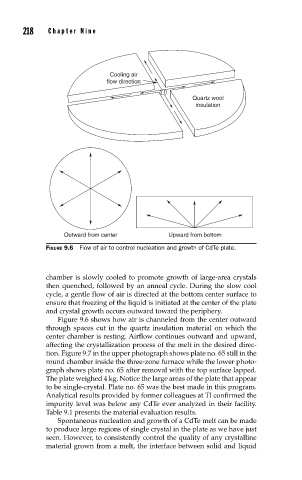

FIGURE 9.6 Flow of air to control nucleation and growth of CdTe plate.

chamber is slowly cooled to promote growth of large-area crystals

then quenched, followed by an anneal cycle. During the slow cool

cycle, a gentle flow of air is directed at the bottom center surface to

ensure that freezing of the liquid is initiated at the center of the plate

and crystal growth occurs outward toward the periphery.

Figure 9.6 shows how air is channeled from the center outward

through spaces cut in the quartz insulation material on which the

center chamber is resting. Airflow continues outward and upward,

affecting the crystallization process of the melt in the desired direc-

tion. Figure 9.7 in the upper photograph shows plate no. 65 still in the

round chamber inside the three-zone furnace while the lower photo-

graph shows plate no. 65 after removal with the top surface lapped.

The plate weighed 4 kg. Notice the large areas of the plate that appear

to be single-crystal. Plate no. 65 was the best made in this program.

Analytical results provided by former colleagues at TI confirmed the

impurity level was below any CdTe ever analyzed in their facility.

Table 9.1 presents the material evaluation results.

Spontaneous nucleation and growth of a CdTe melt can be made

to produce large regions of single crystal in the plate as we have just

seen. However, to consistently control the quality of any crystalline

material grown from a melt, the interface between solid and liquid