Page 62 - Chalcogenide Glasses for Infrared Optics

P. 62

40 Cha pte r T w o

400

40%

Si 7 As 5 Te 8

Softening point 300 50% Si 5 As 5 Te 10

65%

200

Si 6 As 8 Te 26

75%

6

Si As 9 Te 45

100

0 20 40 60 80 100

Percent substitution (Ge for Si)

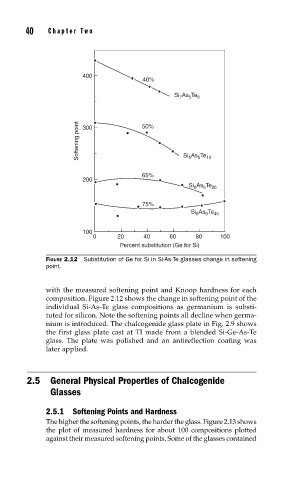

FIGURE 2.12 Substitution of Ge for Si in Si-As-Te glasses change in softening

point.

with the measured softening point and Knoop hardness for each

composition. Figure 2.12 shows the change in softening point of the

individual Si-As-Te glass compositions as germanium is substi-

tuted for silicon. Note the softening points all decline when germa-

nium is introduced. The chalcogenide glass plate in Fig. 2.9 shows

the first glass plate cast at TI made from a blended Si-Ge-As-Te

glass. The plate was polished and an antireflection coating was

later applied.

2.5 General Physical Properties of Chalcogenide

Glasses

2.5.1 Softening Points and Hardness

The higher the softening points, the harder the glass. Figure 2.13 shows

the plot of measured hardness for about 100 compositions plotted

against their measured softening points. Some of the glasses contained