Page 233 - Challenges in Corrosion Costs Causes Consequences and Control(2015)

P. 233

PROTECTIVE COATINGS 211

Miscellaneous

(Overhead, profir, etc.)

12%

Abrasives

5%

Other labor Surface

9% prepartion

40%

Coating

application

15%

Coating material cost

19%

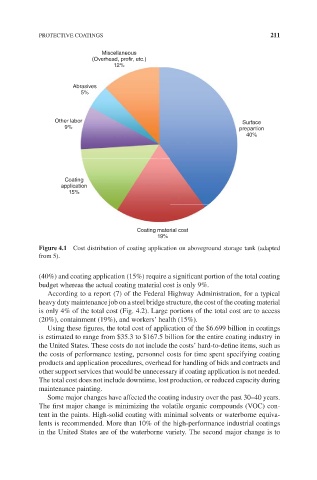

Figure 4.1 Cost distribution of coating application on aboveground storage tank (adapted

from 5).

(40%) and coating application (15%) require a significant portion of the total coating

budget whereas the actual coating material cost is only 9%.

According to a report (7) of the Federal Highway Administration, for a typical

heavy duty maintenance job on a steel bridge structure, the cost of the coating material

is only 4% of the total cost (Fig. 4.2). Large portions of the total cost are to access

(20%), containment (19%), and workers’ health (15%).

Using these figures, the total cost of application of the $6.699 billion in coatings

is estimated to range from $35.3 to $167.5 billion for the entire coating industry in

the United States. These costs do not include the costs’ hard-to-define items, such as

the costs of performance testing, personnel costs for time spent specifying coating

products and application procedures, overhead for handling of bids and contracts and

other support services that would be unnecessary if coating application is not needed.

The total cost does not include downtime, lost production, or reduced capacity during

maintenance painting.

Some major changes have affected the coating industry over the past 30–40 years.

The first major change is minimizing the volatile organic compounds (VOC) con-

tent in the paints. High-solid coating with minimal solvents or waterborne equiva-

lents is recommended. More than 10% of the high-performance industrial coatings

in the United States are of the waterborne variety. The second major change is to