Page 234 - Challenges in Corrosion Costs Causes Consequences and Control(2015)

P. 234

212 CORROSION CONTROL AND PREVENTION

Coating material

Waste disposal 4%

5%

Environment Access Costs

monitoring 9% 28%

Surface

preparation

10%

Coating

application

10%

Containment

19%

Worker health

15%

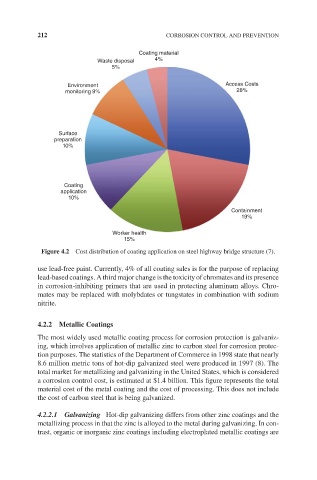

Figure 4.2 Cost distribution of coating application on steel highway bridge structure (7).

use lead-free paint. Currently, 4% of all coating sales is for the purpose of replacing

lead-based coatings. A third major change is the toxicity of chromates and its presence

in corrosion-inhibiting primers that are used in protecting aluminum alloys. Chro-

mates may be replaced with molybdates or tungstates in combination with sodium

nitrite.

4.2.2 Metallic Coatings

The most widely used metallic coating process for corrosion protection is galvaniz-

ing, which involves application of metallic zinc to carbon steel for corrosion protec-

tion purposes. The statistics of the Department of Commerce in 1998 state that nearly

8.6 million metric tons of hot-dip galvanized steel were produced in 1997 (8). The

total market for metallizing and galvanizing in the United States, which is considered

a corrosion control cost, is estimated at $1.4 billion. This figure represents the total

material cost of the metal coating and the cost of processing. This does not include

the cost of carbon steel that is being galvanized.

4.2.2.1 Galvanizing Hot-dip galvanizing differs from other zinc coatings and the

metallizing process in that the zinc is alloyed to the metal during galvanizing. In con-

trast, organic or inorganic zinc coatings including electroplated metallic coatings are