Page 235 - Challenges in Corrosion Costs Causes Consequences and Control(2015)

P. 235

PROTECTIVE COATINGS 213

80

Thickness of

zinc coating

70

0.5 mils

60 2.1 mils

10 mils

Service life, years 40

50 mils

50

30

20

10

0

Rural Tropical marine Moderate Heavy

industrial industrial

Environment

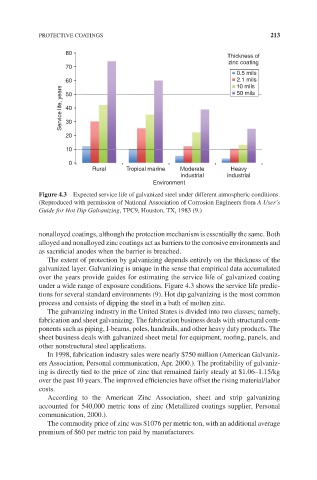

Figure 4.3 Expected service life of galvanized steel under different atmospheric conditions.

(Reproduced with permission of National Association of Corrosion Engineers from A User’s

Guide for Hot Dip Galvanizing, TPC9, Houston, TX, 1983 (9.)

nonalloyed coatings, although the protection mechanism is essentially the same. Both

alloyed and nonalloyed zinc coatings act as barriers to the corrosive environments and

as sacrificial anodes when the barrier is breached.

The extent of protection by galvanizing depends entirely on the thickness of the

galvanized layer. Galvanizing is unique in the sense that empirical data accumulated

over the years provide guides for estimating the service life of galvanized coating

under a wide range of exposure conditions. Figure 4.3 shows the service life predic-

tions for several standard environments (9). Hot dip galvanizing is the most common

process and consists of dipping the steel in a bath of molten zinc.

The galvanizing industry in the United States is divided into two classes; namely,

fabrication and sheet galvanizing. The fabrication business deals with structural com-

ponents such as piping, I-beams, poles, handrails, and other heavy duty products. The

sheet business deals with galvanized sheet metal for equipment, roofing, panels, and

other nonstructural steel applications.

In 1998, fabrication industry sales were nearly $750 million (American Galvaniz-

ers Association, Personal communication, Apr. 2000.). The profitability of galvaniz-

ing is directly tied to the price of zinc that remained fairly steady at $1.06–1.15/kg

over the past 10 years. The improved efficiencies have offset the rising material/labor

costs.

According to the American Zinc Association, sheet and strip galvanizing

accounted for 540,000 metric tons of zinc (Metallized coatings supplier, Personal

communication, 2000.).

The commodity price of zinc was $1076 per metric ton, with an additional average

premium of $60 per metric ton paid by manufacturers.