Page 283 - Chemical Process Equipment - Selection and Design

P. 283

250 DRYERS AND COOLING TOWERS

TABLE 9.74 continued)

(c) Pan Dryer

Sodium Potassium Arsenic

Thiosulphate Zeolite Pentoxide

Dryer diameter 6ftOin. 2ft3in. 8ftOin.

Dryer depth 2ftOin. 1 R 0 in. 2ftOin.

Capacity (Ib product) 12 cwt 14 Ib 2; ton/day

Initial moisture (% w/w basis) 37 40 35

Final moisture (% w/w basis) 0 1 2-3

Method of heating steam steam steam

Atmospheric (a) or vacuum (b) (b) 26 Hg (a) 60 Ib/in.*/gauge (b)

Drying temperature: material (OF)

Drying temperature: shelf (“F) 153C

Bulk density product (Ib/ft3)

Drying time (hr/batch) 5 3 8

Material of construction ss MS ss

[Courtesy A.P.V.-Mitchell (Dryers) Ltd., Williams-Gardner, 19711.

Condensate or

hot water return

by customer

(a)

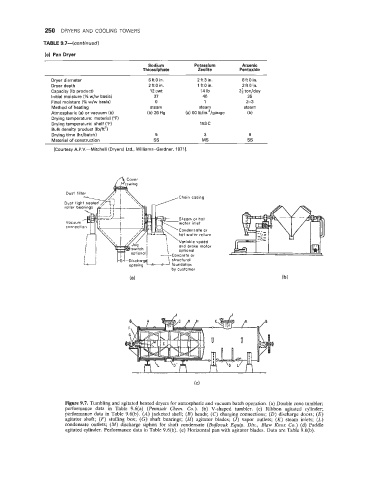

Figure 9.7. Tumbling and agitated heated dryers for atmospheric and vacuum batch operation. (a) Double cone tumbler;

performance data in Table 9.6(a) (Pennsalt Chem. Co.). (b) V-shaped tumbler. (c) Ribbon agitated cylinder;

performance data in Table 9.6(b). (A) jacketed shell; (B) heads; (C) charging connections; (D) discharge doors; (E)

agitator shaft; (F) stuffing box; (G) shaft bearings; (H) agitator blades; (J) vapor outlets; (K) steam inlets; (L)

condensate outlets; (M) discharge siphon for shaft condensate (Bu$ovak Equip. Diu., Bluw Knox Co.) (d) Paddle

agitated cylinder. Performance data in Table 9.6(b). (e) Horizontal pan with agitator blades. Data are Table 9.6(b).