Page 284 - Chemical Process Equipment - Selection and Design

P. 284

9.6. ROTARY CYLINDRICAL DRYERS 251

r

Id)

Figwe 9.7-(continued)

ments

MATERIAL FALL1 NG PILE OF MATERIAL

TO TRAY BELOW FROM TRAY ABOVE

feeder, Extruder Exhaust fans Exhaust fan

Zone I Zone 2 Zone 3

i Air up Air down I Cooler

I Sealing partition Transfer section

(C) (d)

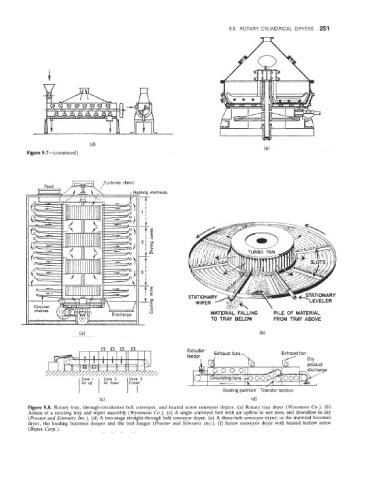

Figure 9.8. Rotary tray, through-circulation belt conveyor, and heated screw conveyor dryers. (a) Rotary tray dryer (Wyssrnont Co.). (b)

Action of a rotating tray and wiper assembly (Wyssrnont Co.). (c) A single conveyor belt with air upflow in wet zone and downflow in dry

(Proctor and SC~JQP~Z hc.). (d) A two-stage straight-through belt conveyor dryer. (e) A three-belt conveyor dryer; as the material becomes

dryer, the loading becomes deeper and the belt longer (Proctor and Schwnrtz Znc.). (f) Screw conveyor dryer with heated hollow screw

(Bepex Corp.).