Page 287 - Chemical Process Equipment - Selection and Design

P. 287

254 DRYERS AND COOLING TOWERS

/Friction seal

Girth aear

4

assembly Drive

assembly Discharae

--__)_wI) -

U

Recycle conveyor

Filter

n Elevator

Vent gas

Air

lock

Air heater Feeder

Entering' ~wmw

air f Recycle -

mixer

Feeder

Steam tube dryer

Product discharge

(b) (C)

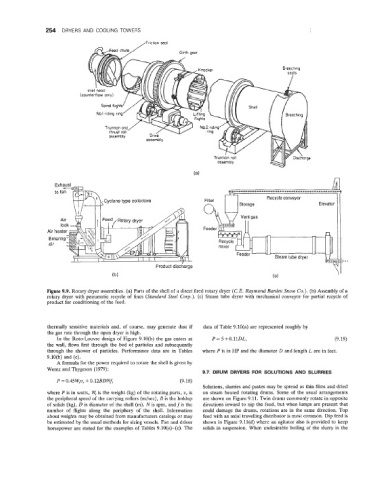

Figure 9.9. Rotary dryer assemblies. (a) Parts of the shell of a direct fired rotary dryer (C.E. Raymond Bartlett Snow Co.). (b) Assembly of a

rotary dryer with pneumatic recycle of fines (Standard Steel Corp.). (c) Steam tube dryer with mechanical conveyor for partial recycle of

product for conditioning of the feed.

thermally sensitive materials and, of course, may generate dust if data of Table 9.10(a) are represented roughly by

the gas rate through the open dryer is high.

In the Roto-Louvre design of Figure 9.10(b) the gas enters at P = 5 + O.llDL, (9.19)

the wall, flows first through the bed of particles and subsequently

through the shower of particles. Performance data are in Tables where P is in HP and the diameter D and length L are in feet.

9.10(b) and (c).

A formula for the power required to rotate the shell is given by

Wentz and Thygeson (1979):

9.7. DRUM DRYERS FOR SOLUTIONS AND SLURRIES

P = O.45Wtu, + O.l2BDNf, (9.18)

Solutions, slurries and pastes may be spread as thin films and dried

where P is in watts, W, is the weight (kg) of the rotating parts, u, is on steam heated rotating drums. Some of the usual arrangements

the peripheral speed of the carrying rollers (m/sec), B is the holdup are shown on Figure 9.11. Twin drums commonly rotate in opposite

of solids (kg), D is diameter of the shell (m), N is rpm, and f is the directions inward to nip the feed, but when lumps are present that

number of flights along the periphery of the shell. Information could damage the drums, rotations are in the same direction. Top

about weights may be obtained from manufacturers catalogs or may feed with an axial travelling distributor is most common. Dip feed is

be estimated by the usual methods for sizing vessels. Fan and driver shown in Figure 9.11(d) where an agitator also is provided to keep

horsepower are stated for the examples of Tables g.lO(a)-(c). The solids in suspension. When undesirable boiling of the slurry in the