Page 292 - Chemical Process Equipment - Selection and Design

P. 292

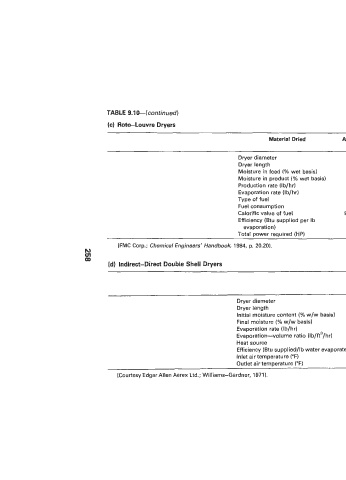

TABLE 9.104continoed)

(c) Roto-Louvre Dryers

Material Drled Ammonium Foundry Sand Metallurgical

Sulfate Coke

Dryer diameter 2ft7in. 6ft4in. lOft3in.

Dryer length loft 24 ft 30 ft

Moisture in feed (% wet basis) 2.0 6.0 18.0

Moisture in product (% wet basis) 0.1 0.5 0.5

Production rate (Ib/hr) 2500 32,000 38,000

Evaporation rate (Ib/hr) 50 2130 8110

Type of fuel steam gas oil

Fuel consumption 255 Ib/hr 4630ft3/hr 115 gal/hr

Calorific value of fuel 837 Btu/lb 1000 Btu/ft3 150,000 Btu/gal

Efficiency (Btu supplied per Ib 4370 2170 2135

evaporation)

Total power required (HP) 4 41 78

(FMC Corp.; Chemical Engineers' Handbook, 1984, p. 20.20).

(d) Indirect-Direct Double Shell Dryers

Indirect-Direct Double Shell

Coal Anhydrite Coke

Dryer diameter 7ft6in. 5fr10in. 5ft 10 in.

Dryer length 46ftOin. 35ft0 in. 35ftOin.

Initial moisture content (% w/w basis) 22 6.0 15

Final moisture (% w/w basis) 6 1 .o 1 .o

Evaporation rate (Ib/hr) 5800 2300 1600

Evaporation-volume ratio (lb/ft3/hr) 3.5 3.15 2.2

Heat source coal oil oil

Efficiency (Btu supplied/lb water evaporated) 1250 1250 1340

Inlet air temperature CF) 1200 1350 1350

Outlet air temDerature (OF) 160 160 200

(Courtesy Edgar Allen Aerex Ltd.; Williams-Gardner, 1971).