Page 296 - Chemical Process Equipment - Selection and Design

P. 296

260 DRYERS AND COOLING TOWERS

DER

rfl4- VAPOR OUTLET

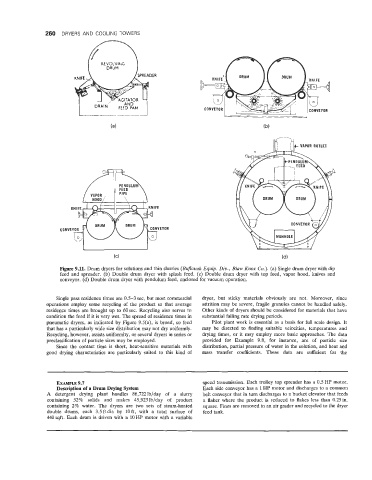

Figure 9.11. Drum dryers for solutions and thin slurries (Bujlouuk Equip. Diu., Bluw Knox Co.). (a) Single drum dryer with dip

feed and spreader. (b) Double drum dryer with splash feed. (c) Double drum dryer with top feed, vapor hood, knives and

conveyor. (d) Double drum dryer with pendulum feed, enclosed for vacuum operation.

Single pass residence times are 0.5-3 sec, but most commercial dryer, but sticky materials obviously are not. Moreover, since

operations employ some recycling of the product so that average attrition may be severe, fragile granules cannot be handled safely.

residence times are brought up to 60sec. Recycling also serves to Other kinds of dryers should be considered for materials that have

condition the feed if it is very wet. The spread of residence times in substantial falling rate drying periods.

pneumatic dryers, as indicated by Figure 9.5(a), is broad, so feed Pilot plant work is essential as a basis for full scale design. It

that has a particularly wide sue distribution may not dry uniformly. may be directed to finding suitable velocities, temperatures and

Recycling, however, assists uniformity, or several dryers in series or drying times, or it may employ more basic approaches. The data

preclassification of particle sizes may be employed. provided for Example 9.8, for instance, are of particle size

Since the contact time is short, heat-sensitive materials with distribution, partial pressure of water in the solution, and heat and

good drying characteristics are particularly suited to this kind of mass transfer coefficients. These data are sufficient for the

EXAMPLE 9.7 speed transmission. Each trolley top spreader has a 0.5 HP motor.

Description of a Drum Drying System Each side conveyor has a 1 HP motor and discharges to a common

A detergent drying plant handles 86,7221b/day of a slurry belt conveyor that in turn discharges to a bucket elevator that feeds

containing 52% solids and makes 45,9231b/day of product a flaker where the product is reduced to flakes less than 0.25in.

containing 2% water. The dryers are two sets of steam-heated square. Fines are removed in an air grader and recycled to the dryer

double drums, each 3.5ftdia by loft, with a total surface of feed tank.

440 sqft. Each drum is driven with a 10 HP motor with a variable