Page 291 - Chemical Process Equipment - Selection and Design

P. 291

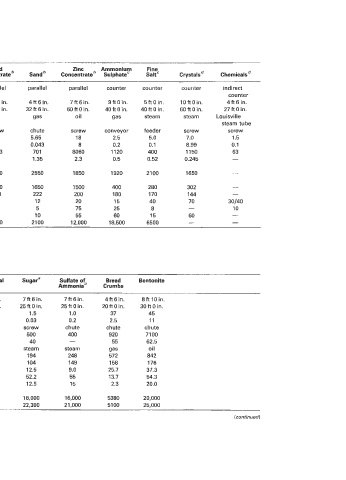

TABLE 9.10. Performance Data of Rotary Dryers

(a) Direct Heated Dryers

__.____ ~~

Sugar Beet Calcium Blast bead Zinc Ammonium Fine

Pulp“ Carbonatee Furnace Slag” Concentrateb Sandb Concentrateb Sulphate” SaltC Crystals Chemicalsd

Air flow parallel parallel parallel parallel parallel parallel counter counter counter indirect

counter

Dryer length 9ft2in. 6ft3in. 7ft2in. 4ft6in. 4tt6in. 7ft6in. 9ftOin. 5ftOin. 10ftOin. 4ft6in.

Dryer length 46 ft 0 in. 34ftOin. 40 ft 0 in. 35ftOin. 32 ft 6 in. 60 ft 0 in. 40 ft 0 in. 40ftOin. 60 ft 0 in. 27 ft 0 in.

Method of heating oil oil oil oil gas oil gas steam steam Louisville

steam tube

Method of feed screw belt belt screw chute screw conveyor feeder screw screw

Initial moisture (% w/w) 82 13.5 33 14 5.65 18 2.5 5.0 7.0 1.5

Final moisture (% w/w) 10 0.5 nil 8 0.043 8 0.2 0.1 8.99 0.1

Evaporation (Ib/hr) 34,000 6000 11,600 1393 701 8060 1120 400 1150 63

Capacity (Ib evaporated/ft3 dryer 11 6 7 2.5 1.35 2.3 0.5 0.52 0.245 -

volume)

Efficiency (Btu supplied/water 1420 1940 1710 2100 2550 1850 1920 2100 4 650

evaporated)

Inlet air temperature VF) 1560 1560 1560 1300 1650 1500 400 280 302

Outlet air temperature (“F) 230 220 248 200 222 200 180 170 144

Residence time (av. min) 20 25 30 20 12 20 15 40 70

-

Fan HP 70 40 50 20 5 75 25 8

Motive HP 15 20 25 10 10 55 60 15 60

Fan capacity (std. air ft3/min) 45000 8500 18,000 2750 21 00 12,000 18.500 6500 -

*Courtesy Buell Ltd.

bCourtesy Head Wrightson (Stockton) itd.

Courtesy Edgar Allen Aerex Ltd.

Courtesy Constantin Engineers Ltd.-Louisville Dryers; Williams-Gardner, 1971.

(b) Roto-Louvre Dryers

Bone Meal Sugar” Sulfate of Bread Bentonite

Ammonia” Crumbs

~

Dryer diameter 7ft6in. 7ft6in. 7ft6in. 4ft6in. 8ftlOin.

Dryer length 12ftOin. 25ftOin. 25 ft 0 in. 20ftOin. 30ftOin.

Initial moisture (% w/w basis) 17.0 1.5 1 .o 37 45

Final moisture (% w/w basis) 7.0 0.03 0.2 2.5 11

Method of feed screw screw chute chute chute

Evaporation rate (Ib/hr) 1660 500 400 920 7100

Efficiency (Btu supplied/lb evaporation) 74.3 40 - 55 62.5

Method of heating steam steam steam gas oil

Inlet air temperature (“F) 203 194 248 572 842

Outlet air temperature (“F) 122 104 149 158 176

Residence time, rnin 9.3 12.5 9.0 25.7 37.3

Fan HP (absorbed) 49.3 52.2 55 13.7 54.3

Motive HP (absorbed) 8 12.5 15 2.3 20.0

Fan capacity (ft3/min)

Inlet 9560 48,000 16,000 5380 20,000

Outlet 14,000 22,300 21,000 5100 25,000

a Combined two-stage dryer-cooler. (continued)

(Courtesy Dunford and Elliott Process Engineering Ltd.; Williams-Gardner, 1971).