Page 295 - Chemical Process Equipment - Selection and Design

P. 295

(e) Steam Tube Dryers

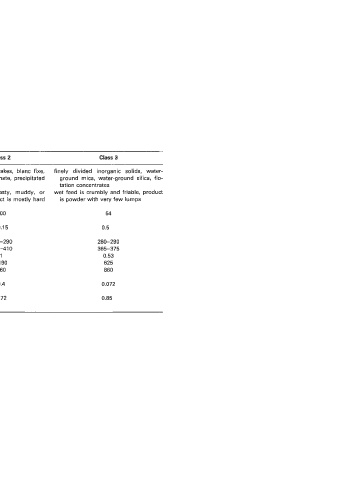

Class 1 Class 2 Class 3

Class of materials high moisture organic, distillers' pigment filter cakes, blanc fixe, finely divided inorganic solids, water-

grains, brewers' grains, citrus barium carbonate, precipitated ground mica, water-ground silica, flo-

Pulp chalk tation concentrates

Descriation of class wet feed is granular and damp but wet feed is pasty, muddy, or wet feed is crumbly and friable, product

not sticky or muddy and dries to sloppy, product is mostly hard is powder with very few lumps

granular meal pellets

Normal moisture content of wet 233 100 54

feed (% dry basis)

& Normal moisture content of product 11 0.15 0.5

(D (% dry basis)

Normal temperature of wet feed (K) 310-320 280-290 280-290

Normal temperature of product (K) 350-355 380-41 0 365-375

Evaporation per product (kg) 2 1 0.53

Heat load per Ib product (kJ) 2250 1190 625

Steam pressure normally used (kPa 860 860 860

gauge)

Heating surface required per kg 0.34 0.4 0.072

product (m2)

Steam consumption per kg product 3.33 1.72 0.85

(kg)

(Chemical Engineers' Handbook, 1984).