Page 301 - Chemical Process Equipment - Selection and Design

P. 301

9.9. FLUIDIZED BED DRYERS 265

Recirculation

duct -Stack

Expansion

I bellows

ID fan

I

Change over flap

1

3ted rnoterial

mixer

2 Bottom bend . ~ . ~

hammer mill

Combustion chamber

(b)

I. Fan

2. Ring duct

3. Manifold

4. Injector

5. Air outlet

6. Feeder

7. Filter

8. Heater

9. Cyclone 7

IO. Disintegrator

/I. Bag filter

12. Discharge

(C)

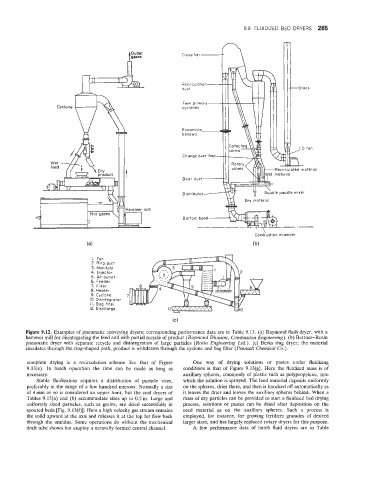

Figure 9.12. Examples of pneumatic conveying dryers; corresponding performance data are in Table 9.13. (a) Raymond flash dryer, with a

hammer mill for disintegrating the feed and with partial recycle of product (Raymond Division, Combustion Engineering). (b) Buttner-Rosin

pneumatic dryer with separate recycle and disintegration of large particles (Rosin Engineering Ltd.). (c) Berks ring dryer; the material

circulates through the ring-shaped path, product is withdrawn through the cyclone and bag filter (Penmalt Chemical Co.).

complete drying is a recirculation scheme like that of Figure One way of drying solutions or pastes under fluidizing

9.131(e). In batch opelration the time cain be made as long as conditions is that of Figure 9.13(g). Here the fluidized mass is of

necessary. auxiliary spheres, commonly of plastic such as polypropylene, into

Stable fluidnzation requires a distribution of particle sizes, which the solution is sprayed. The feed material deposits uniformly

preferably in the range of a few hundred microns. Normally a size on the spheres, dries there, and then is knocked off automatically as

of 4mm or so is considered an upper limit, but the coal dryers of it leaves the drier and leaves the auxiliary spheres behind. When a

Tables 9.15(a) and (b) accommodate sizes up to 0.5in. Large and mass of dry particles can be provided to start a fluidized bed drying

uniformly sized particles, such as grains, are dried successfully in process, solutions or pastes can be dried after deposition on the

spouted beds [Fig. 9.13(f)]: Here a high velocity gas stream entrains seed material as on the auxiliary spheres. Such a process is

the solid upward at the axis and releases it at the top for flow back employed, for instance, for growing fertilizer granules of desired

through the annulus. Some operations do without the mechanical larger sizes, and has largely replaced rotary dryers for this purpose.

draft tube shown but employ a naturally formed central channel. A few performance data of batch fluid dryers are in Table