Page 305 - Chemical Process Equipment - Selection and Design

P. 305

9.10. SPRAY DRYERS 269

A

P

Gas Out

A

I

Solids Feed -

Alternative

Gas Distributor Plate

fe Cas and Solids Feed - Flow

I

Solid

--- Gas Flow

(e) (f)

Figure 9.13-(continued)

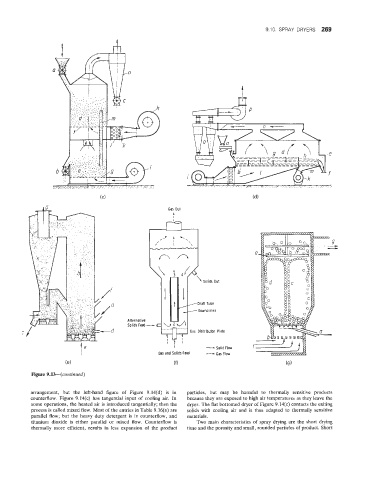

arrangement, but the left-hand figure of Figure 9.14(d) is in particles, but may be harmful to thermally sensitive products

counterflow. Figure 9.14(c) has tangential input of cooling air. In because they are exposed to high air temperatures as they leave the

some operations, the heated air is introduced tangentially; then the dryer. The flat bottomed dryer of Figure 9.14(c) contacts the exiting

process is called mixed flow. Most of the entries in Table 9.16(a) are solids with cooling air and is thus adapted to thermally sensitive

parallel flow; but the heavy duty detergent is in counterflow, and materials.

titanium dioxide is either parallel or mixed flow. Counterflow is Two main characteristics of spray drying are the short drying

thermally more efficient, results in less expansion of the product time and the porosity and small, rounded particles of product. Short