Page 285 - Chemical Process Equipment - Selection and Design

P. 285

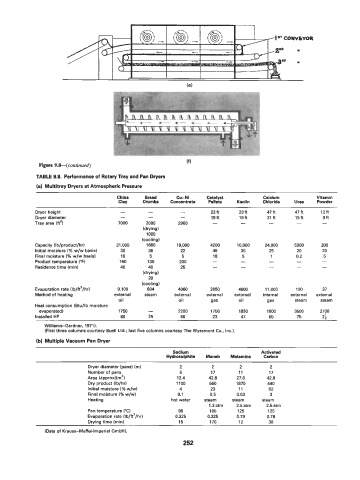

Figure 9.8-(continued)

TABLE 9.8. Performance of Rotary Tray and Pan Dryers

(a) Multitray Dryers at Atmospheric Pressure

China Bread Cu-Ni Catalyst Calcium Vitamin

Clay Crumbs Concentrate Pellets Kaolin Chloride Urea Powder

Dryer height 23 ft 23 ft 47 ft 47 ft 12ft

Dryer diameter - - - 19 ft 19 ft 31 ft 15ft 9ft

Tray area (ft’) 7000 2000 2900 - - - - -

(drying)

1000

(cooling)

Capacity (Ib/product/hr) 31,000 1680 19,000 4200 10,000 24,000 5000 200

Initial moisture (% w/w basis) 30 36 22 45 35 25 20 20

Final moisture (% w/w basis) 10 5 5 18 5 1 0.2 5

Product temperature (“F) 160 100 200 - - - - -

Residence time (min) 40 40 25

(drying)

20

(cooling)

Evaporation rate (Ib/ft2/hr) 9.100 804 4060 2050 4600 1 1,000 100 37

Method of heating external steam external external external internal external external

oil oil gas oil gas steam steam

Heat consumption (Btu/lb moisture

evaporated) 1750 - 2200 1750 1850 1800 3500 2700

Installed HP 80 25 60 23 47 65 75 2;

Williams-Gardner, 1971).

(First three columns courtesy Buell Ltd.; last five columns courtesy The Wyssmont Co., Inc.).

(b) Multiple Vacuum Pan Dryer

Sodium Activated

Hydrosulphite Maneb Melamine Carbon

Dryer diameter (pans) (m) 2 2 2 2

Number of pans 5 17 11 17

Area (approx)(mz) 12.4 42.8 27.6 42.8

Dry product (Ib/hr) 1100 660 1870 440

Initial moisture (% w/w) 4 23 11 62

Final moisture (% w/w) 0.1 0.5 0.03 3

Heating hot water steam steam steam

1.3 atm 2.5 atm 2.5 atm

Pan temperature (“C) 98 105 125 125

Evaporation rate (Ib/ft’/hr) 0.325 0.325 0.79 0.78

Drying time (min) 15 170 12 30

(Data of Krauss-Maffei-Imperial GmbH).

252