Page 389 - Chemical Process Equipment - Selection and Design

P. 389

352 DISINTEGRATION, AGGLOMERATION, AND SIZE SEPARATION OF PARTICULATE SOLIDS

surface of the bed of particles. The tumbling action then distributes performance data in addition to those shown with Figure 12.7 are:

the liquid uniformly through the mass.

The disk granulator of Figure 12.7 is a shallow pan, inclined

45-70" to the horizontal and rotating at speeds of 10-30rpm. The Material Diameter (mm) kg/(min)(m2)

ratio of pan diameter to collar height is 3-5. The variety of Iron ore 10-25 11.4

materials to which this equipment is applied is indicated by the Cement flour 18

listing of part (e) with this figure and in Table 12.14. As the rotation Fertilizer 1.6-3.3 14.3

proceeds, fresh solids and spray are charged continually. The finer

particles settle to the bottom, the largest remain at the top and then The data of Figure 12.7(c) for cement kiln feed are 42-

overflow the collar and constitute the product. Because of the size 44 kg/(min)(m2).

stratification, the product of disk granulation is more uniform in size Pans also are made with height more nearly equal to the

than of drum granulators which discharge a mixed product. Some diameter. In one such device the material is continually lifted onto

Feed 1-1

Feed inlet

~JGagebar

/ I \

f 1

Product Product outlet

(a) (b)

Y

Grinding disks

Product outlet

(4

Feed inlet

Product

outlet

._ Grinding

' stones

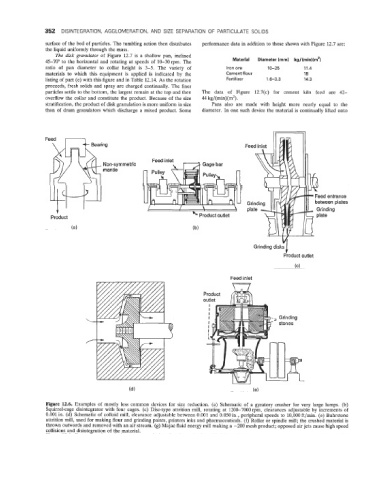

Figure 12.6. Examples of mostly less common devices for size reduction. (a) Schematic of a gyratory crusher for very large lumps. (b)

Squirrel-cage disintegrator with four cages. (c) Disc-type attrition mill, rotating at 1200-7000 rpm, clearances adjustable by increments of

0.001 in. (d) Schematic of colloid mill, clearance adjustable between 0.001 and 0.050 in., peripheral speeds to 10,000 ft/min. (e) Buhrstone

attrition mill, used for making flour and grinding paints, printers inks and pharmaceuticals. (f) Roller or spindle mill; the crushed material is

thrown outwards and removed with an air stream. (g) Majac fluid energy mill making a -200 mesh product; opposed air jets cause high speed

collisions and disintegration of the material.