Page 390 - Chemical Process Equipment - Selection and Design

P. 390

12.5. PARTICLE SIZE ENLARGEMERT 353

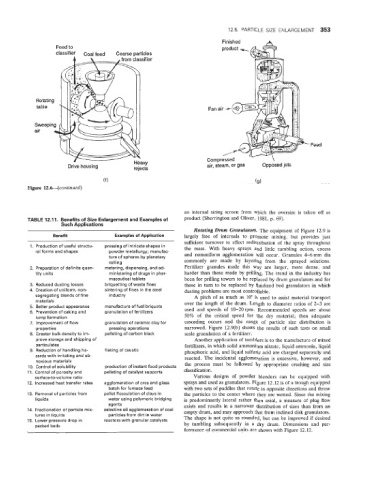

Feed to

classifies coal feed coarse particles

Feed

air, steam, or gas Opposed jets

an internal sizing screen from which the oversize is taken off as

TABLE 12.11. 13enefits of Size Enlargement and Examples of product (Sherrington and Oliver, 1981, p. 69).

!Such Applications

Rotating Drum Granulators. The equipment of Figure 12.9 is

Benefit Examples of Application largely free of internals to promote mixing, but provides just

sufficient turnover to effect redistribution of the spray throughout

1. Production OF useful structu- pressing of intricate shapes in the mass. With heavy sprays and little tumbling action, excess

ral forms andl shapes powder metallurgy; manufac-

ture of spheres by planetary and nonuniform agglomeration will occur. Granules 4-6 mm dia

rolling commonly are made by layering from the sprayed solutions.

2. Preparation of definite quan- metering, dispensing, and ad- Fertilizer granules made this way are larger, more dense, and

tity units ministering of drugs in phar- harder than those made by prilling. The trend in the industry has

maceutical tablets been for prilling towers to be replaced by drum granulators and for

3. Reduced dusting losses briquetting of waste fines those in turn to be replaced by fluidized bed granulators in which

4. Creation of uniform, non- sintering of fines in the steel dusting problems are most controllable.

segregating blends of fine industry A pitch of as much as 10" is used to assist material transport

materials over the length of the drum. Length to diameter ratios of 2-3 are

5. Better product appearance manufacture of fuel briquets

6. Prevention of caking and granulation of fertilizers used and speeds of 10-20rpm. Recommended speeds are about

lump formation 50% of the critical speed for the dry material; then adequate

7. lrnprovement of flow granulation of ceramic clay for cascading occurs and the range of particle size distribution is

properties pressing operations narrowed. Figure 12.9(b) shows the results of such tests on small

8. Greater bulk density to im- pelleting of carbon black scale granulation of a fertilizer.

prove storage and shipping of Another application of tumblers is to the manufacture of mixed

particulates fertilizers, in which solid ammonium nitrate, liquid ammonia, liquid

9. Reduction of handling ha- flaking of caustic phosphoric acid, and liquid sulfuric acid are charged separately and

zards with irritating and ob- reacted. The incidental agglomeration is excessive, however, and

noxious materiais the process must be followed by appropriate crushing and size

'IO. Control of solubility production of instant food products

14. Control of porosity and peileting of catalyst supports classification.

su dace-to-vo Iu me ratio Various designs of powder blenders can be equipped with

12. Increased hat transfer rates agglomeration of ores and glass sprays and used as granulators. Figure 12.12 is of a trough equipped

batch for furnace feed with two sets of paddles that rotate in opposite directions and throw

13. Removal of particles from pellet flocculation of clays in the particles to the center where they are wetted. Since the mixing

liquids water using polymeric bridging is predominantly lateral rather than axial, a measure of plug flow

agents exists and results in a narrower distribution of sizes than from an

14. Fractionation of particle mix- selective oil agglomeration of coal empty drum, and may approach that from inclined disk granulators.

tures in liquids particles from dirt in water

15. Lower pressure drop in reactors with granular catalysts The shape is not quite as rounded, but can be improved if desired

packed beds by tumbling subsequently in a dry drum. Dimensions and per-

formance of commercial units are shown with Figure 12.12.